Image 1 of 1

Image 1 of 1

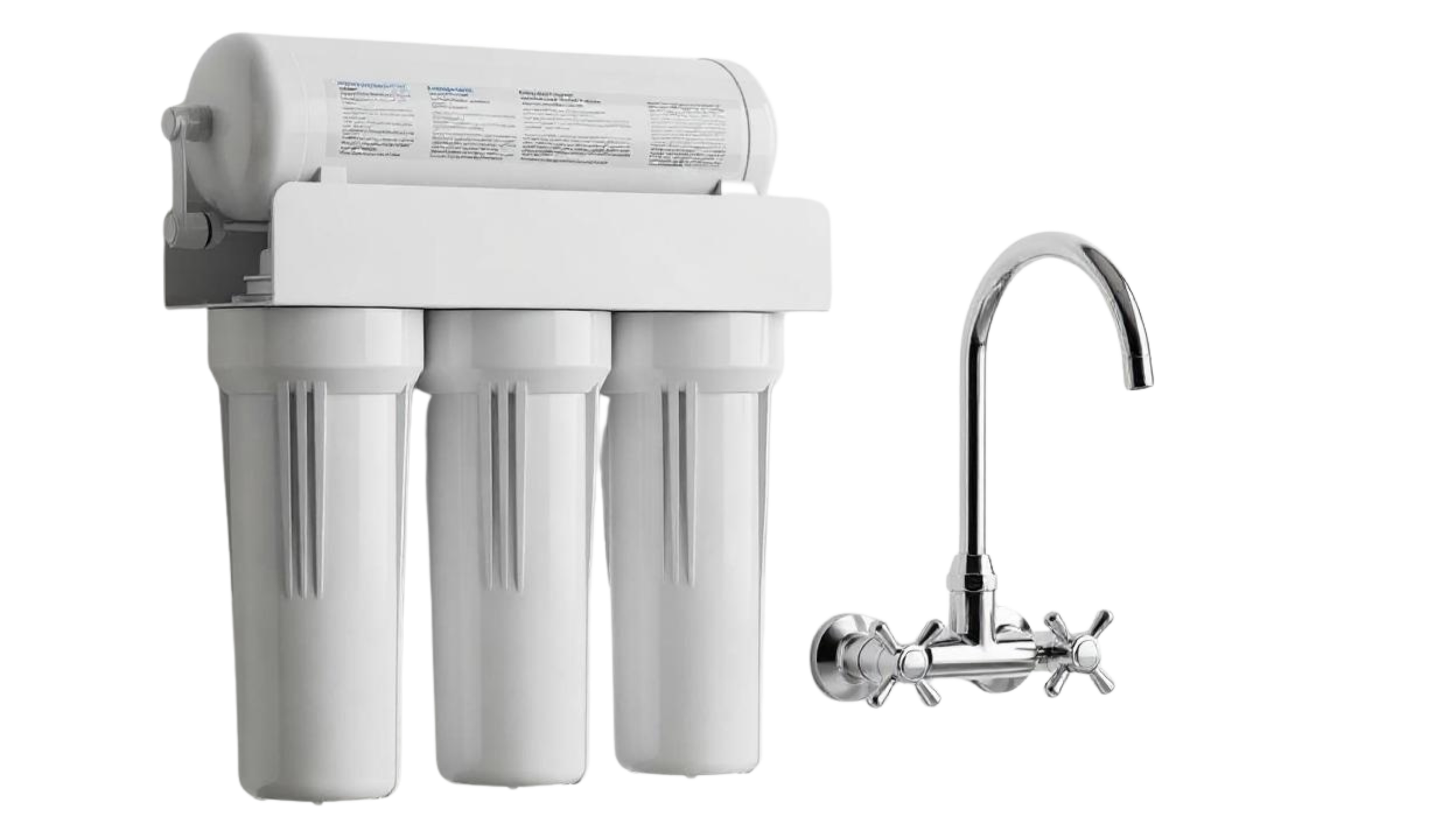

W-F306

Product Description

The W-F306 is a dual-stage water filtration system designed for under-sink or countertop installation in residential settings. It features a modern, compact design and uses high-quality components to ensure effective removal of impurities such as:

Sand

Rust

Dirt

Chlorine

Organic compounds

Unpleasant odors and taste

With its two-stage filtration and fast-connect fittings, the W-F306 offers both performance and ease of use for daily water purification needs.

Size

Dimensions (L × W × H): 25cm × 6 cm ×34 cm Plastic

Material

Housing material: Made entirely of high-quality food-grade plastic, offering durability, chemical resistance, and lightweight performance.

Filter setup: Dual-stage filtration system consisting of:

Stage 1 – Sediment filter (PP cotton): Captures large particles such as sand, rust, and dirt to protect downstream filters and appliances.

Stage 2 – Carbon block filter (CTO or GAC): Removes chlorine, odors, organic compounds, and improves overall taste and clarity.

Top panel: Modern, sleek design with a decorative cover (possibly with display or labeling area), enhancing the aesthetic appeal for kitchen or under-sink installation.

Sealing components: Fitted with rubber or silicone O-rings at key joints to ensure airtight and watertight performance under pressure.

Connectors: Quick-connect plastic fittings for fast installation and maintenance.

Production Steps

Material sourcing: Collect food-grade plastic for housings, filter media (PP, carbon), sealing rings, and connector parts.

Plastic molding: Use injection molding to create the filter housings, caps, and decorative top panel.

Filter cartridge assembly: Prepare sediment and carbon cartridges by packing and sealing the media into standard-size filter shells.

System assembly: Install filters into the dual housing unit, attach the top panel, and connect inlet/outlet ports.

Sealing ring installation: Add silicone or rubber O-rings to ensure leak-proof connections at all junctions.

Leak and pressure testing: Run water through the unit to verify structural integrity, seal tightness, and performance.

Final inspection: Perform quality checks on appearance, dimensions, and filtration function.

Packaging: Clean, label, and pack the unit with user instructions and installation accessories.

Product Description

The W-F306 is a dual-stage water filtration system designed for under-sink or countertop installation in residential settings. It features a modern, compact design and uses high-quality components to ensure effective removal of impurities such as:

Sand

Rust

Dirt

Chlorine

Organic compounds

Unpleasant odors and taste

With its two-stage filtration and fast-connect fittings, the W-F306 offers both performance and ease of use for daily water purification needs.

Size

Dimensions (L × W × H): 25cm × 6 cm ×34 cm Plastic

Material

Housing material: Made entirely of high-quality food-grade plastic, offering durability, chemical resistance, and lightweight performance.

Filter setup: Dual-stage filtration system consisting of:

Stage 1 – Sediment filter (PP cotton): Captures large particles such as sand, rust, and dirt to protect downstream filters and appliances.

Stage 2 – Carbon block filter (CTO or GAC): Removes chlorine, odors, organic compounds, and improves overall taste and clarity.

Top panel: Modern, sleek design with a decorative cover (possibly with display or labeling area), enhancing the aesthetic appeal for kitchen or under-sink installation.

Sealing components: Fitted with rubber or silicone O-rings at key joints to ensure airtight and watertight performance under pressure.

Connectors: Quick-connect plastic fittings for fast installation and maintenance.

Production Steps

Material sourcing: Collect food-grade plastic for housings, filter media (PP, carbon), sealing rings, and connector parts.

Plastic molding: Use injection molding to create the filter housings, caps, and decorative top panel.

Filter cartridge assembly: Prepare sediment and carbon cartridges by packing and sealing the media into standard-size filter shells.

System assembly: Install filters into the dual housing unit, attach the top panel, and connect inlet/outlet ports.

Sealing ring installation: Add silicone or rubber O-rings to ensure leak-proof connections at all junctions.

Leak and pressure testing: Run water through the unit to verify structural integrity, seal tightness, and performance.

Final inspection: Perform quality checks on appearance, dimensions, and filtration function.

Packaging: Clean, label, and pack the unit with user instructions and installation accessories.