Precision Tooling & Mold Fabrication Services

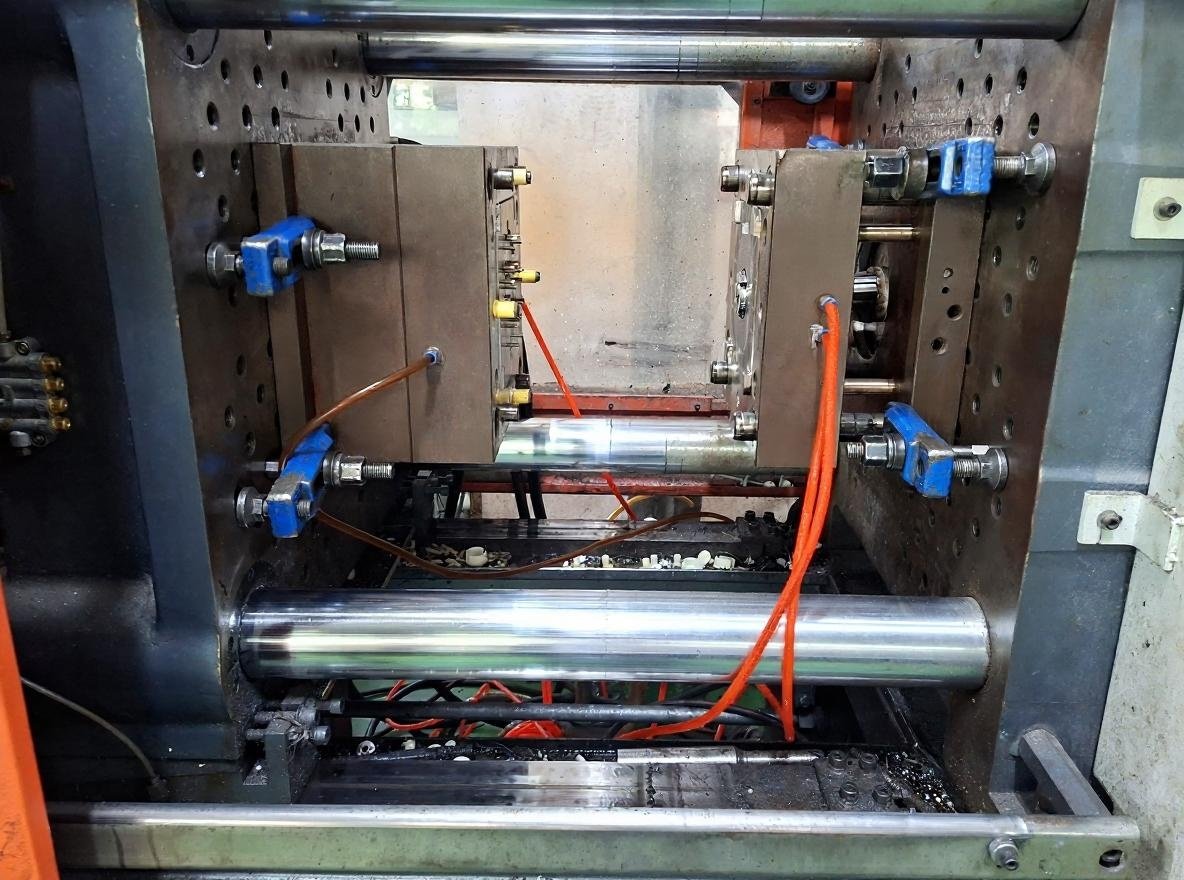

We design and fabricate high-precision molds in-house to ensure faster lead times, consistent part quality, and better control over revisions.

INTRODUCTION

Precision Molds Built for Long-Term Performance

In plastic manufacturing, "tooling" refers to the creation of molds used in injection molding or other forming processes. These molds define the shape, surface texture, and structural detail of the final product. A well-built tool not only ensures consistent product quality, it also influences your unit cost, lead time, and ability to scale production.

Export Tools vs. Production Tools

We offer two main tooling options depending on your production strategy, all molds are fabricated in-house, giving us full control over quality, lead time, and ongoing modifications.

Export Tool

Export tools are designed for clients who plan to run production at their own factory or through a third-party manufacturer. These molds are built to international standards and delivered with full documentation, including steel certifications, mold flow analysis, and maintenance guides.

Best for:

Brands with existing manufacturing partners

Long-term production at off-site facilities

International shipping and off-site use

Production Tool

Production tools are used within our facility and are optimized for our equipment. These molds are built, tested, and maintained by our engineering team throughout the product’s lifecycle. They are designed for long-term use with consistent output, easy maintenance, and high repeatability.

Best for:

Clients seeking full-service manufacturing

High-volume production with consistent reorders

Long-term product lines

Mold Grades & Lifespan

We build molds in various classes to match your volume, budget, and product needs, helping control costs and maintain quality from the start. We recommend the right tooling class based on your production goals, timeline, and budget. Every tool is evaluated for cycle speed, ejection, and long-term performance.

| Tooling Class | Estimated Lifespan | Steel Type | Typical Use Case |

|---|---|---|---|

| Class 101 | 1,000,000+ cycles | Hardened steel (e.g., H13, S136) | High-volume production, long-term SKUs, tight tolerances |

| Class 102 | Up to 1,000,000 cycles | Semi-hardened steel (e.g., P20) | Medium to high-volume products with moderate complexity |

| Class 103 | Up to 500,000 cycles | Pre-hardened steel or P20 | Moderate production runs, limited product life |

| Class 104 | Up to 100,000 cycles | Softer steel or aluminum | Low-volume production, early market testing |

| Class 105 | Fewer than 500 cycles | Aluminum or prototype materials | Prototype tools, short-term testing, concept validation |

Why Choose Our Tooling Service

30+ Years of Experience

We've built a strong manufacturing base with deep expertise.

In-House Testing

Every mold is trialed and inspected before shipment or entering production.

Mold Engineering

Molds are crafted for excellent surface finish, long-term durability, and high repeatability.

Lifetime Maintenance

We provide lifetime care and maintenance for all molds used in our in-house production.

Flexible Material Options

We work with a wide range of tooling materials, including aluminum, P20, H13, and more.

Full-Cycle Support

We provide lifetime care and maintenance for all molds used in our in-house production.

FAQs

-

We use high-quality tool steel (e.g., P20, H13, S136) for durability and precision, based on your budget and production volume.

-

Standard steel molds take 45-60 days. Simpler or soft molds can be completed faster.

-

You do. Once paid, the mold is your property, and we store and maintain it for production.

-

Yes, minor changes can be made. Major revisions may require a new mold insert or rework.

-

Yes. We provide mold flow simulation to predict filling, warpage, and cooling issues before cutting steel.

-

In some cases, yes. We’ll evaluate material compatibility and recommend the best approach.

Learn More About Our Tooling Services

For further information on tooling and mold fabrication services, please feel free to contact us. Whether you need a one-time export mold or full-service production support, we’re ready to help you develop the right tooling for your product.