Custom Glass Fabrication for Modern Bathrooms

We offer in-house glass fabrication to bring your custom bathroom designs to life with full OEM/ODM support.

INTRODUCTION

What is Glass Fabrication?

Glass fabrication is the industrial process of shaping and modifying raw glass into functional and finished components for various applications. Through a combination of cutting, forming, and strengthening techniques, glass is transformed to meet specific design, safety, and performance requirements. Commonly used in architecture, interior design, and consumer products, glass fabrication plays a key role in creating both structural and decorative elements especially in modern bathroom environments performance.

Processed Glass for Modern Bathrooms

MADE FOR BATHROOMS

In modern bathroom design, glass plays a key role in creating clean, spacious, and elegant environments. Our processed glass is carefully fabricated to meet the functional and aesthetic demands of today’s bathrooms, combining style with safety and durability. Whether it’s for frameless shower enclosures, glass partitions, doors, or decorative panels, each piece is shaped, polished, and tempered to ensure flawless performance and a premium finish.

Our Capabilities

We offer a full suite of glass processing techniques to match the needs of each project:

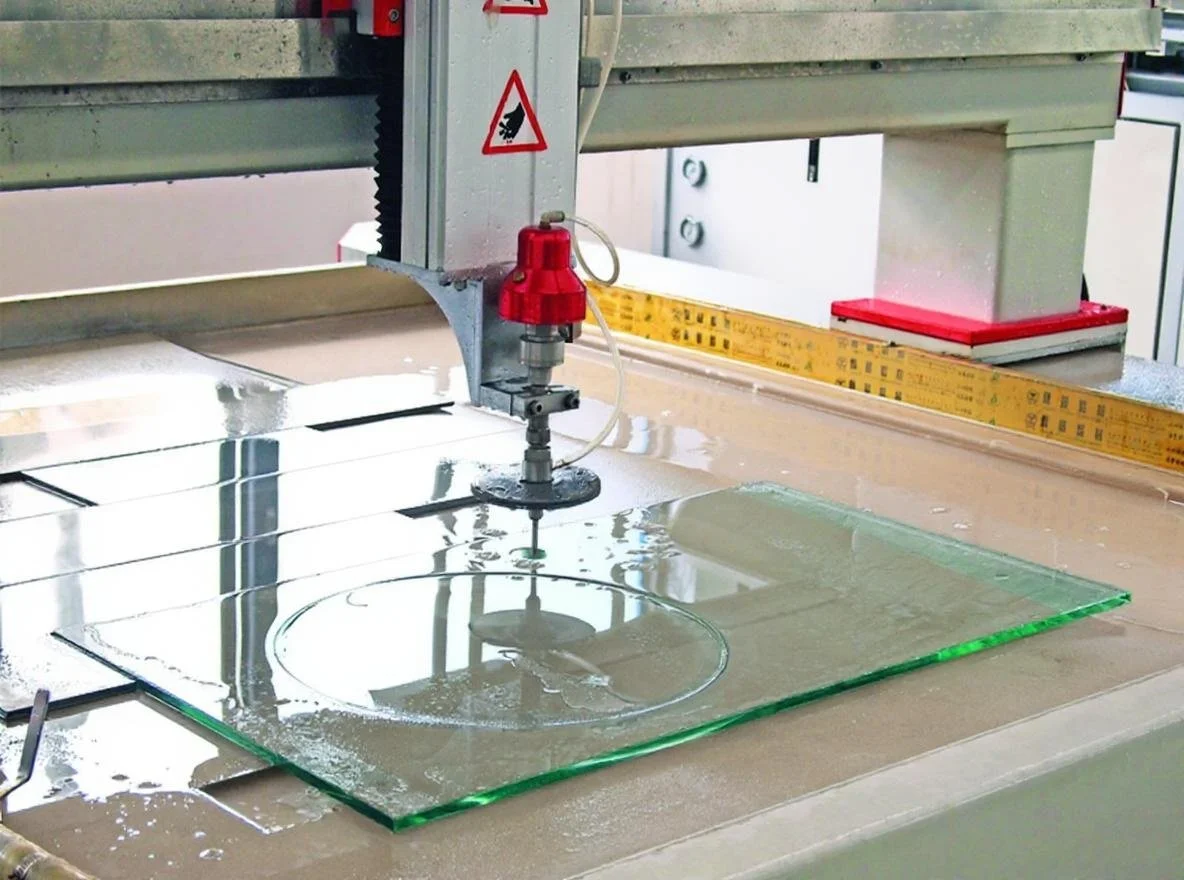

Cutting

We cut large glass sheets into smaller pieces using precision cutting machines. For more complex shapes or detailed project requirements, we use water jet cutting to achieve smooth, accurate edges with minimal stress on the material.

Drilling

We add holes and notches to accommodate brackets, hinges, handles, or other hardware. Our drilling methods are designed to maintain structural integrity and alignment, even on tempered glass.

Stamping / Printing

Glass can be permanently marked using screen printing techniques. This allows us to apply safety stamps, logos, or simple decorative details with durable ink that bonds securely to the surface.

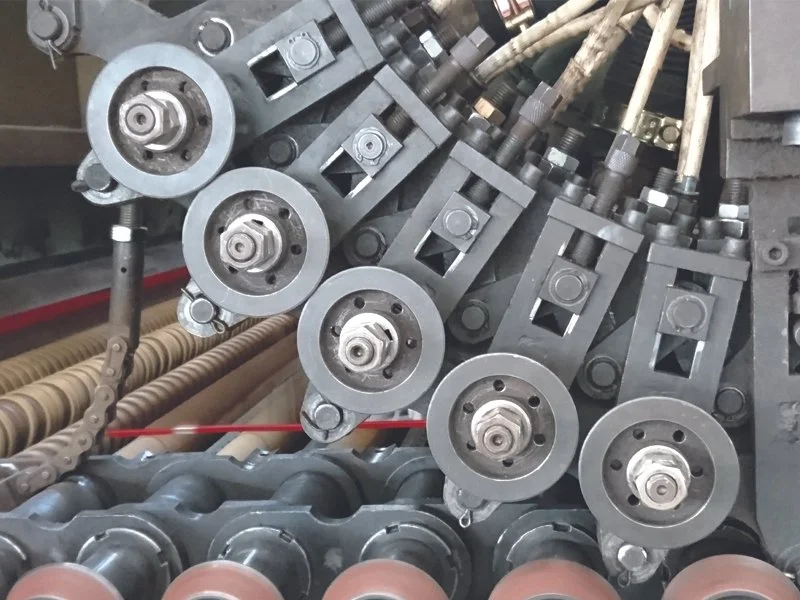

Grinding / Edging

Edges are refined and smoothed to eliminate sharpness, improve safety, and prepare the glass for installation. Available edge finishes include flat, pencil, and beveled styles.

Tempering

Glass is heat-strengthened to improve durability and thermal resistance. This process meets required safety standards for use in wet or high-impact bathroom environments.

Additional / Processes

In addition to standard fabrication, we offer a range of additional processes to enhance the functionality and appearance of our glass products. These include laminating for multi-layered safety glass, bending for curved panels or enclosures, coating for anti-fog or easy-clean surfaces, and polishing to improve edge clarity and overall surface finish.

Learn More About Glass Fabrication

For further information on glass fabrication, please feel free to contact us.

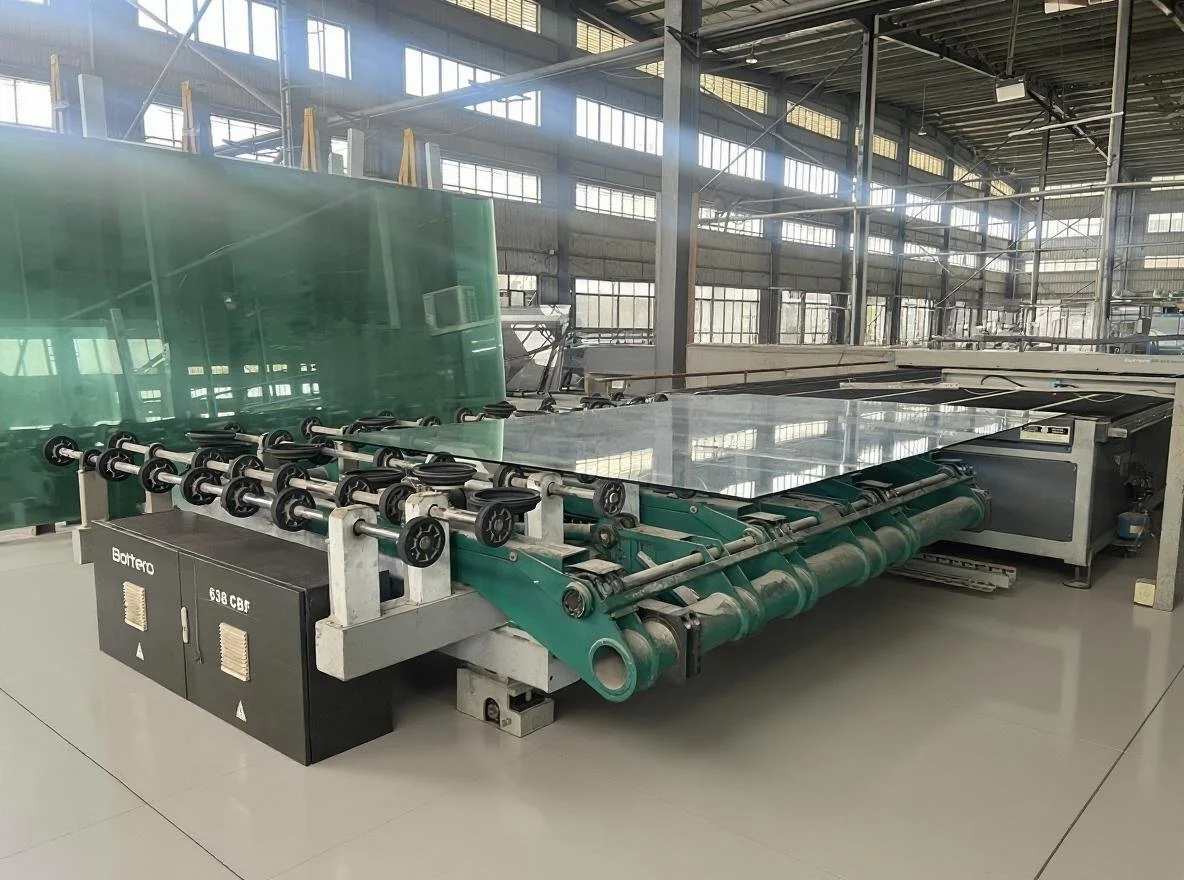

In-House Glass Fabrication Facility

VERTICAL INTEGRATION

Our in-house glass fabrication facility, located in Foshan, is equipped to deliver high-quality, custom glass components for a wide range of modern bathroom applications. By managing the entire process on-site, we ensure consistent quality, faster turnaround times, and the flexibility to support both OEM and ODM projects, tailored to meet your exact specifications.

Why Choose Our Glass Fabrication Services

End-to-End Control

We handle every stage of the fabrication process internally, from cutting to coating. This gives us greater oversight and helps maintain consistent quality.

Experience That Delivers

With 30 years of experience supporting bathroom brands and OEMs, we understand the requirements of both design and engineering teams.

Custom-Fit Precision

Our team works closely with you to deliver glass components that are dimensionally accurate and installation-ready, no secondary adjustments required.

Flexible Batch Sizes

Whether you need short runs or full-scale production, we’re equipped to handle your volume without compromising lead time.

FAQs

We know you might have a few questions, so we’ve put together some helpful answers to get you started. If you don’t find what you’re looking for, we’re always here to help!

-

We primarily work with tempered safety glass, which is ideal for bathroom applications due to its strength and safety features. We can also process laminated and coated glass depending on your project requirements.

-

Yes, we offer full support for both OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) projects. Whether you have a complete design or need help developing one, we can customize glass components to meet your brand’s specifications.

-

Lead times vary depending on the complexity and volume of the order, but our in-house production in Foshan allows us to offer fast and flexible turnaround times. Contact us for a detailed quote and timeline based on your project.

-

Absolutely. We can cut, bend, and shape glass into custom forms and offer a variety of finishes including polishing, anti-fog coatings, and easy-clean treatments to meet both functional and aesthetic needs.

-

Yes, all our processed glass is manufactured in compliance with relevant international safety and quality standards, ensuring it meets the requirements of global markets.

-

MOQs depend on the type of product and customization level. We’re happy to discuss your needs and offer flexible options for both small and large production runs.