Reliable Plastic Injection Molding Services

From concept to production, we deliver reliable, high-quality plastic parts with full OEM/ODM support.

With over 30 years of experience, we've proudly served more than 700 global customers and successfully completed 6,000+ projects across the sanitary and bathroom industry. From tooling design to precision injection molding, we bring proven value, reliability, and efficiency to every stage of your product development.

Plastic Injection Molding At AQUAmate

INTRODUCTION

What is Injection Molding?

Injection molding is a process that produces plastic parts by injecting molten resin into a mold. It’s one of the most reliable methods for manufacturing high-quality, repeatable components at volume. With decades of experience, we support e-commerce brands, product developers, and manufacturers with end-to-end injection molding services from mold making to final packaging.

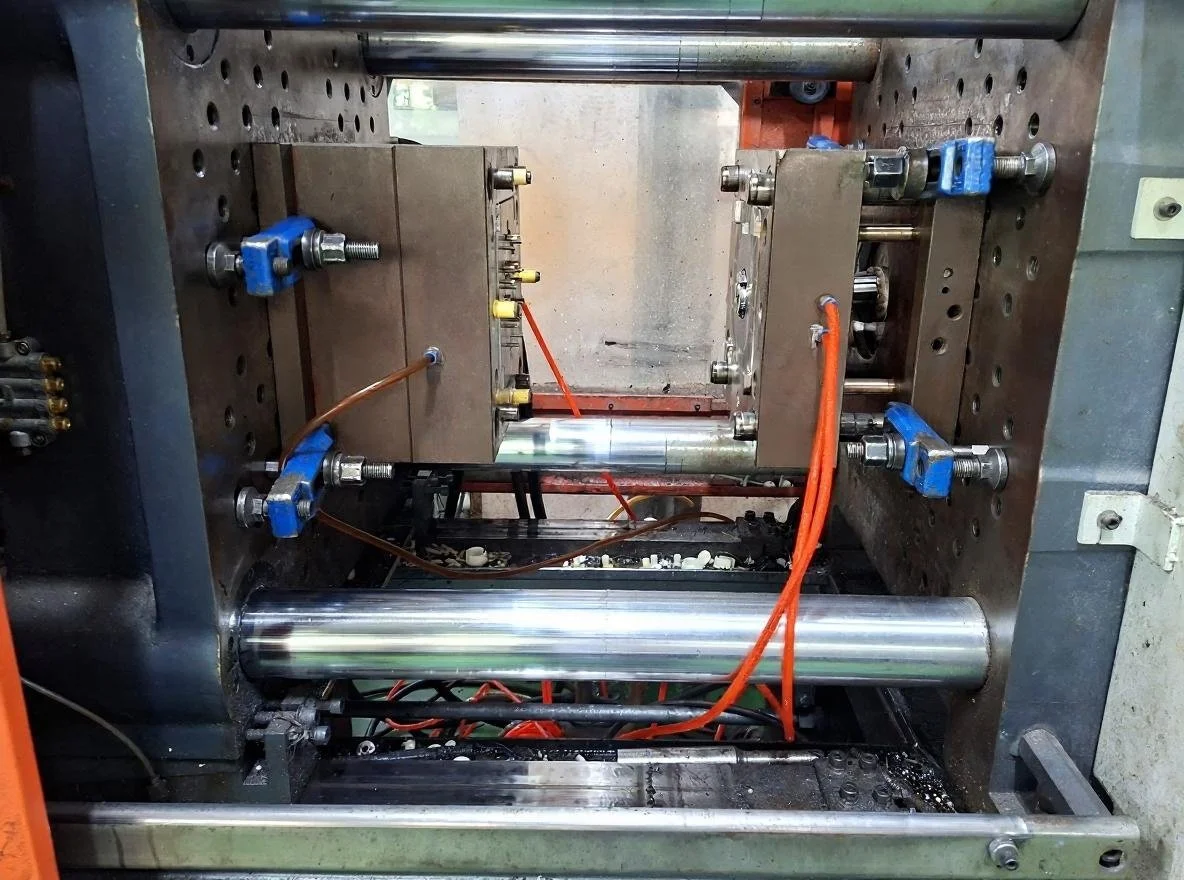

Injection Molding Process at AQUAmate

At AQUAmate, we follow a precise and proven process to ensure every injection molded part meets your exact specifications efficiently, consistently, and with the highest quality standards.

Step 1. Engineering Review

We start by understanding your product requirements, application, and design goals. Our engineering team reviews your drawings or concepts to ensure they are optimized for manufacturability and performance.

Step 2. Mold Design & Tooling

Based on your specifications, we design and produce high-precision molds in-house. Our tooling experts ensure the mold is durable, efficient, and capable of delivering consistent results over time.

Step 3. Material Selection

We work with a wide range of thermoplastics and specialty materials. Our team helps you choose the best material based on mechanical strength, appearance, chemical resistance, and cost-efficiency.

Step 4. Mold Trial & Sample Approval

Before full production begins, we perform mold trials to test fit, function, and appearance. You receive samples for approval to ensure everything meets your expectations.

Step 5. Mass Production

With your approval, we begin full-scale production using advanced injection molding machines and strict quality control.

Step 6. Inspection, Finishing & Packaging

Each part is inspected, optionally post-processed or assembled, and carefully packaged according to your requirements.

Injection Molding Process at AQUAmate

At AQUAmate, we follow a precise and proven process to ensure every injection molded part meets your exact specifications efficiently, consistently, and with the highest quality standards.

Step 1. Engineering Review

We start by understanding your product requirements, application, and design goals. Our engineering team reviews your drawings or concepts to ensure they are optimized for manufacturability and performance.

Step 2. Mold Design & Tooling

Based on your specifications, we design and produce high-precision molds in-house. Our tooling experts ensure the mold is durable, efficient, and capable of delivering consistent results over time.

Step 3. Material Selection

We work with a wide range of thermoplastics and specialty materials. Our team helps you choose the best material based on mechanical strength, appearance, chemical resistance, and cost-efficiency.

Step 4. Mold Trial & Sample Approval

Before full production begins, we perform mold trials to test fit, function, and appearance. You receive samples for approval to ensure everything meets your expectations.

Step 5. Mass Production

With your approval, we begin full-scale production using advanced injection molding machines and strict quality control.

Step 6. Inspection, Finishing & Packaging

Each part is inspected, optionally post-processed or assembled, and carefully packaged according to your requirements.

| Material | Properties | Typical Uses |

|---|---|---|

| ABS | Strong, matte finish | Electronics, tool housings |

| PP | Lightweight, economical | Containers, household items |

| PC | Transparent, heat-resistant | Covers, lenses |

| PA (Nylon) | Durable, mechanical strength | Gears, structural parts |

| TPE / TPU | Flexible, soft touch | Grips, seals, wearables |

| HDPE / LDPE | Chemical-resistant | Storage, piping |

| POM (Acetal) | Low friction, stable dimensions | Bearings, gears, moving parts |

Common Materials We Work With

Learn More About Our Injection Molding Service

For further information on injection molding, please feel free to contact us.

Applications

With over 30 years of experience in sanitary manufacturing, plastic injection molding remains at the core of what we do. Our in-house capabilities allow us to produce precise, durable components designed for daily use in wet, high-humidity environments.

Advantages of Injection Molding

Plastic injection molding offers several key advantages, including fast, high-volume production, excellent surface quality, broad material and color options, and long-lasting, durable tooling. It's an efficient and reliable solution for manufacturing consistent, high-quality parts.

Scalable Production

FastTurnaround

Detailed Features

High Repeatability

Material Efficiency

Diverse Finishes

OUR SUPPORTS

Why Choose Us for Injection Molding

In-House Tooling & Mold Maintenance

We build and service molds on site, improving lead time and control.

Flexible Volumes for Growing Brands

Our production lines support both pilot runs and ongoing orders.

Design Assistance from Day One

We help refine your part design to avoid costly tooling mistakes.

Post-Molding Services

From branding to packaging, we deliver complete, shelf-ready products.

Responsive Project Management

Clear updates and fast communication throughout every stage.

Lastest Articles

Stay up to date with our latest insights, tips, and industry news. From product trends to behind-the-scenes stories, our articles are here to inspire and inform.

FAQs

Have questions? Our FAQs cover common topics about our capabilities, processes, and how we support your project from design to delivery.

-

We work with ABS, PP, PC, PE, PA, and other engineering plastics, depending on your product’s needs.

-

Yes. We design and produce multi-cavity molds to increase efficiency and reduce unit cost.

-

Yes. We support both techniques depending on the product design and materials involved.

-

Absolutely. We provide T1 samples for your review and approval before starting full production.

-

We inspect dimensions, surface finish, and material consistency using standard QC processes.

Sanitaryware is no longer just about functionality, it's about innovation, sustainability, and experience. As we look ahead to 2025 and beyond…