In-House Laboratory

Our on-site lab is equipped to perform a full range of product tests, ensuring every component meets performance, safety, and regulatory standards before it goes to market.

VERTICAL INTEGRATION

In-House Testing Lab

To ensure product quality, safety, and compliance, we operate a fully equipped in-house lab dedicated to performance validation and reliability testing. From corrosion resistance to flow rate accuracy, our lab supports a wide range of functional and environmental tests tailored for bathroom and plumbing products. Every test is conducted by trained technicians using specialized equipment to simulate real-world conditions, allowing us to catch issues early and deliver products that meet global standards.

We use this facility to test sanitary products such as showerheads, hoses, fittings, and filtration systems under rigorous conditions before they go to market.

Testing Equipment

Testing Equipment refers to the precision testing instruments and devices specifically used to test the water pressure, corrosion resistance, flow rate, switch life, surface coating, leak prevention, salt spray and other properties of plumbing hardware and bathroom fixtures, as well as to ensure that the products comply with international and domestic standards.

Salt Spray Tester

Simulates harsh, humid, or coastal environments by exposing products like faucets and showerheads to a controlled salt mist, helping assess corrosion resistance over time.

CNC Showerhead Mode Tester

Performs repeated spray mode changes on showerheads to evaluate durability and ensure consistent long-term performance of switching mechanisms.

Pressure Impulse Tester

Tests how well bathroom products withstand sudden high-pressure changes, helping verify sealing performance and reliability under real-world plumbing conditions.

Shower Filtration Systems Tester

Evaluates how effectively shower filters remove impurities such as chlorine, sediment, and heavy metals from water, supporting health and water quality standards.

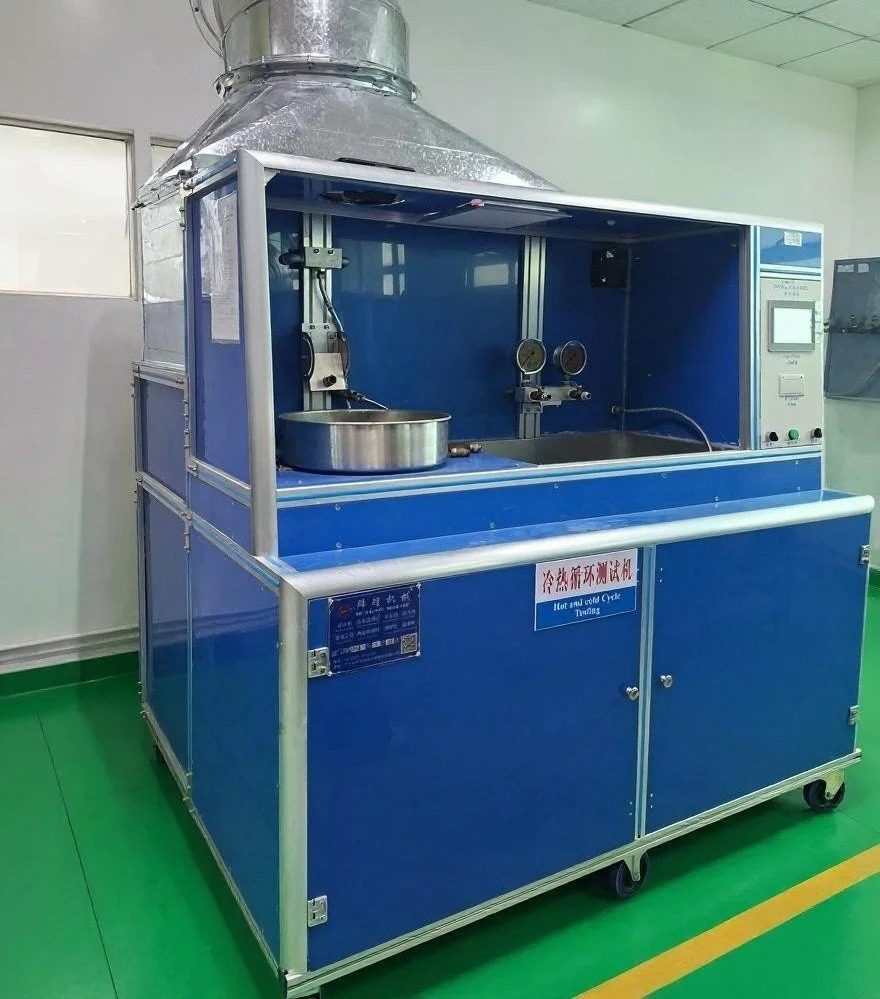

Hot and Cold-Water Cycling Test Machine

Simulates alternating hot and cold water exposure to test the durability and sealing performance of sanitary ware under temperature fluctuations.

Hose Tensile Testing Machine

Measures the tensile strength of hoses and connector pipes, checking their ability to resist stretching or pulling forces during regular use.

Assembly/Disassembly Life Cycle Tester

Assesses the mechanical durability and sealing reliability of fittings and components through repeated cycles of assembly and disassembly.

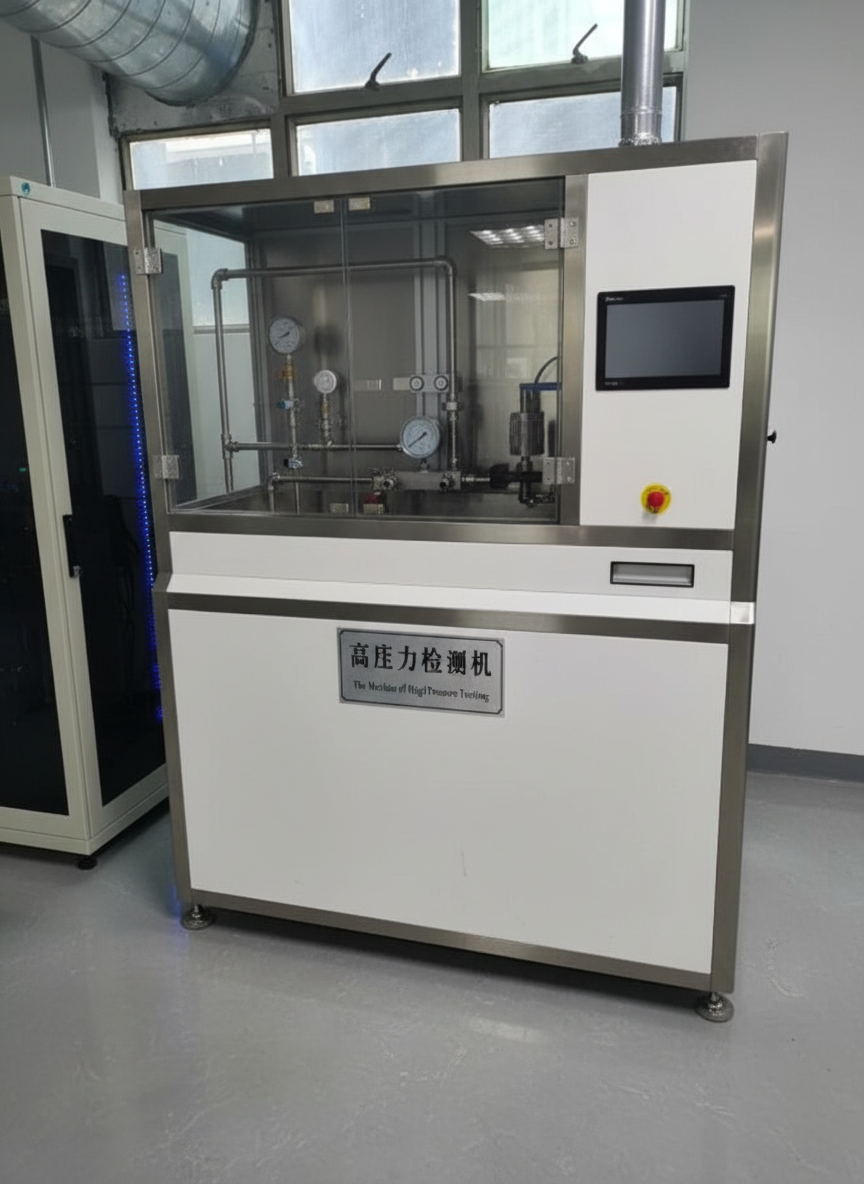

High-Pressure Testing Machine

Applies extreme pressure to bathroom products or piping systems to evaluate their structural integrity and resistance to leaks or ruptures.

Flexible Hose Endurance Tester

Tests hoses under repeated bending, stretching, and pressure cycles to confirm durability and prevent long-term wear or leakage.

Australian Standards Compliance Tester

Used to check if products meet AS/NZS requirements for material safety, strength, durability, and hygiene—crucial for export to Australia and New Zealand.

Constant Temperature & Humidity Tester

Evaluates product performance under stable climate conditions, focusing on sealing, strength, and surface quality over time.

Ventilation Aging Test Chamber

Simulates prolonged exposure to high heat, humidity, or airflow to assess how materials age, including effects like fading, cracking, or structural weakening.

Showerhead Swivel Durability Tester

Checks the endurance of showerhead swivels under continuous movement to ensure lasting function without leaks or instability.

Plastic Material Tensile Tester

Measures the strength, stretch, and elasticity of plastic parts to confirm they meet mechanical performance criteria for product safety and design.

CNC Flow Rate Tester

Precisely measures water flow from faucets and showerheads to verify that products meet design targets and water efficiency standards.

Why Choose Us

Comprehensive In-House Testing

All critical tests conducted under one roof for faster, more reliable results.

Focus on Durability and Safety

We help validate product longevity, mechanical strength, and leak prevention.

Wide Range of Equipment

From flow rate checks to aging simulations, we cover every aspect of product performance.

Streamlined testing helps accelerate development while maintaining quality.

Faster Time to Market

Support for Global Standards

Testing aligned with international regulations, including AS/NZS requirements for exports.

Integrated with Engineering & Production

Direct collaboration ensures faster feedback and smoother problem-solving.

Let’s Build Your Next Product Together

Contact us today to begin your product development journey or request your a free consultation with our engineering team. We’re here to support your innovation with insight, precision, and commitment.