We offer FREE DFM analysis and review your design early to ensure it’s optimized for manufacturing.

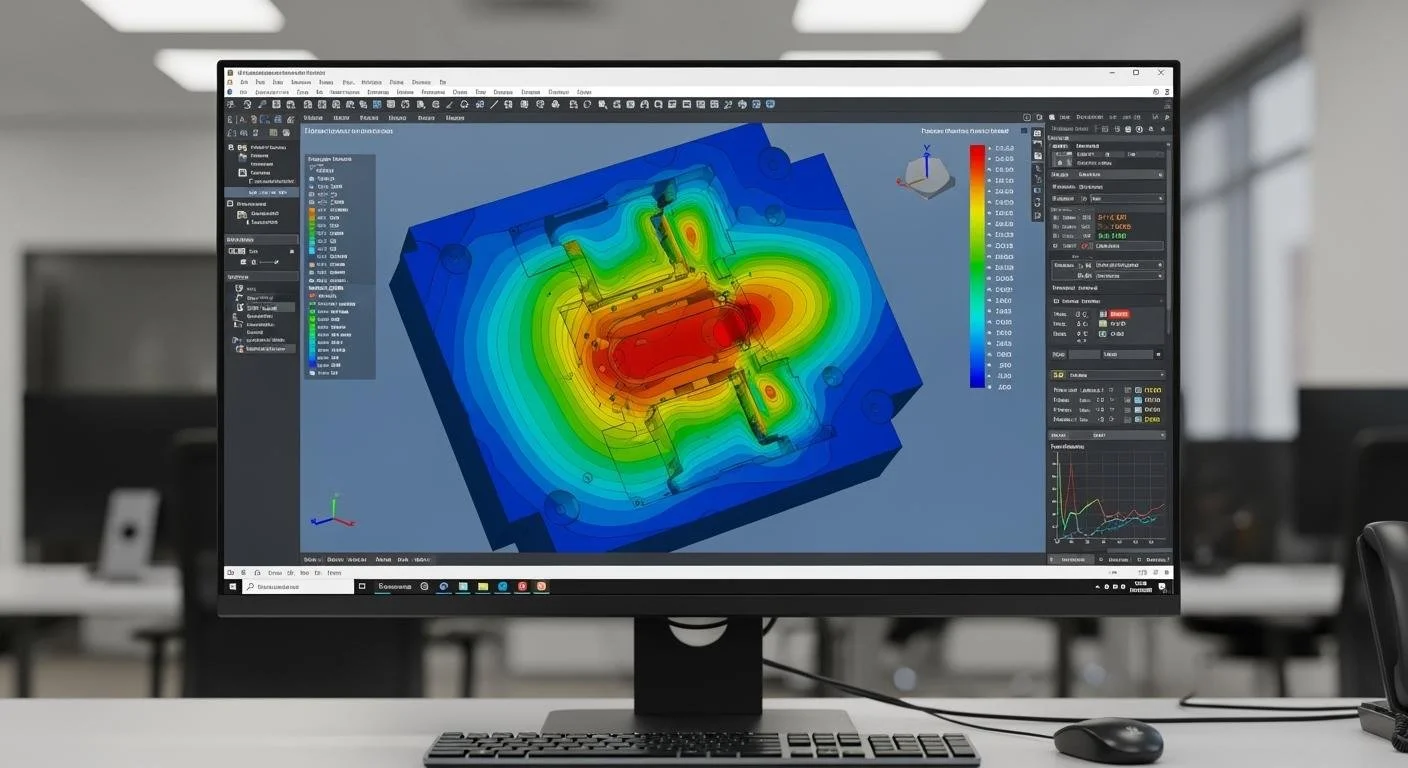

Design for Manufacturing (DFM) Analysis

INTRODUCTION

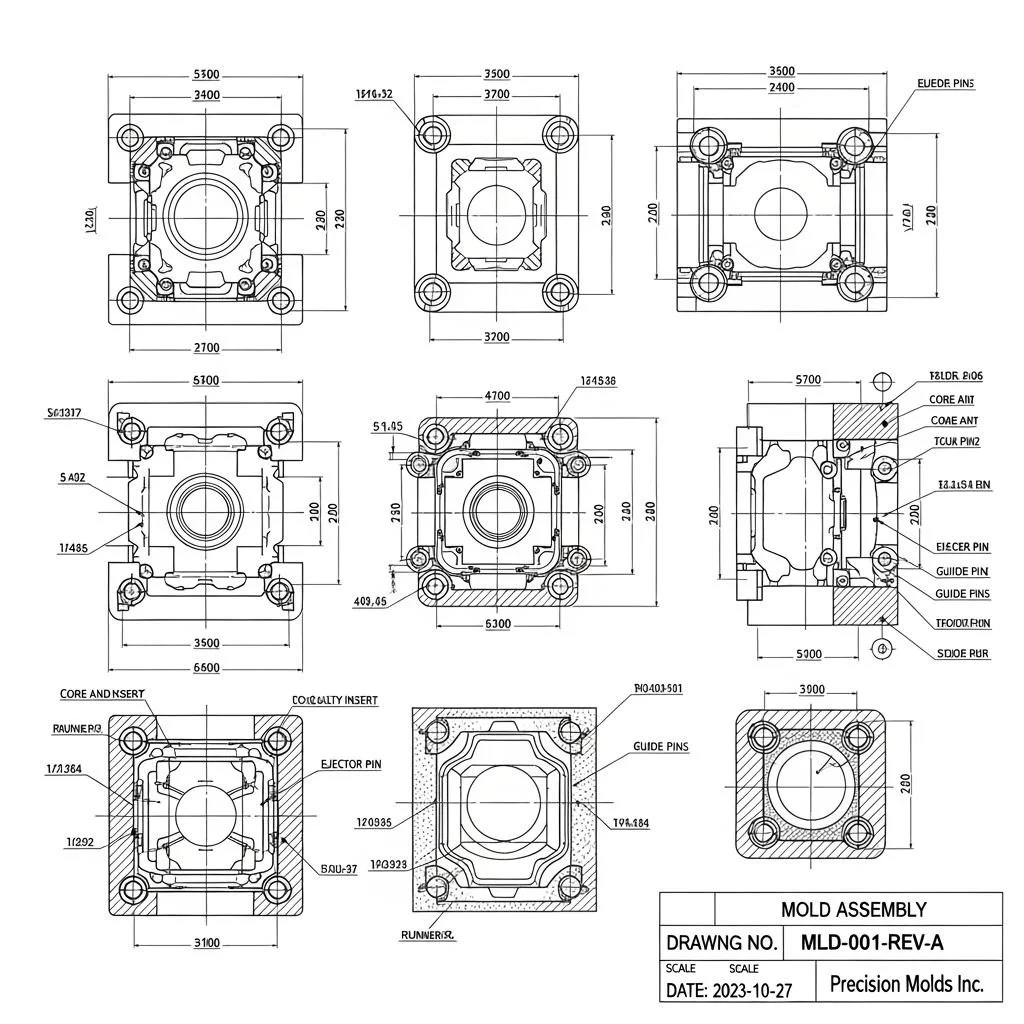

What is DFM analysis

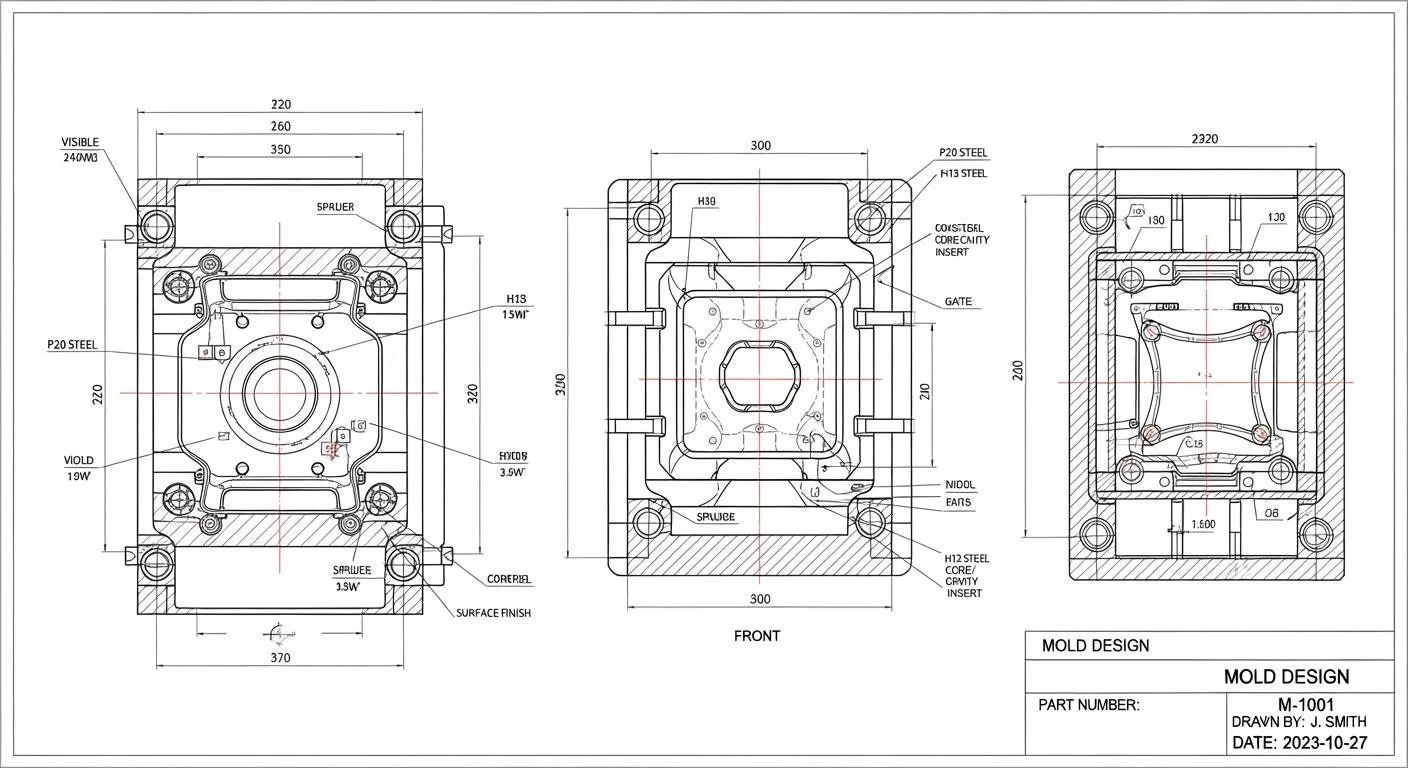

Design for Manufacturing (DFM) analysis is the process of reviewing a product’s design to ensure it can be efficiently produced using real-world materials, processes, and equipment. It aligns the design with manufacturing capabilities by evaluating key factors such as part geometry, wall thickness, material selection, tolerances, assembly methods, and how the design will interact with tooling, ensuring that features can be molded, machined, or assembled without unnecessary complexity.

Why DFM Matters

A well-executed DFM review can make the difference between a smooth project launch and unexpected delays or quality issues.

Improved Manufacturability

We assess if part geometry suits manufacturing, including draft angles, wall thickness, and undercuts.

Assembly Compatibility

For multi-component products, we review how parts will fit and interact during assembly. This includes alignment features, fastening methods, and tolerance stack-up..

Cost Optimization

Consolidating parts or simplifying tool paths can reduce tooling and production costs without compromising function or aesthetics.

Tooling Efficiency

We analyze part interaction with molds or fixtures to ensure proper flow, ejection, cooling, and machinability, improving tool life and cycle times.

Fewer Design Iterations

By identifying potential production issues early, DFM helps reduce the need for multiple rounds of design changes, saving both time and development costs.

Material Suitability

We provide guidance on material selection based on performance, appearance, cost, and processes, ensuring the right match between design and manufacturing.

Ready to optimize your design?

We offer free DFM analysis to help you improve manufacturability before production begins.

Our Process

We follow a collaborative, engineering-led process to help you turn your design into a production-ready solution.

Step 1. Submit Your Design

You send us your CAD files or technical drawings to get started.

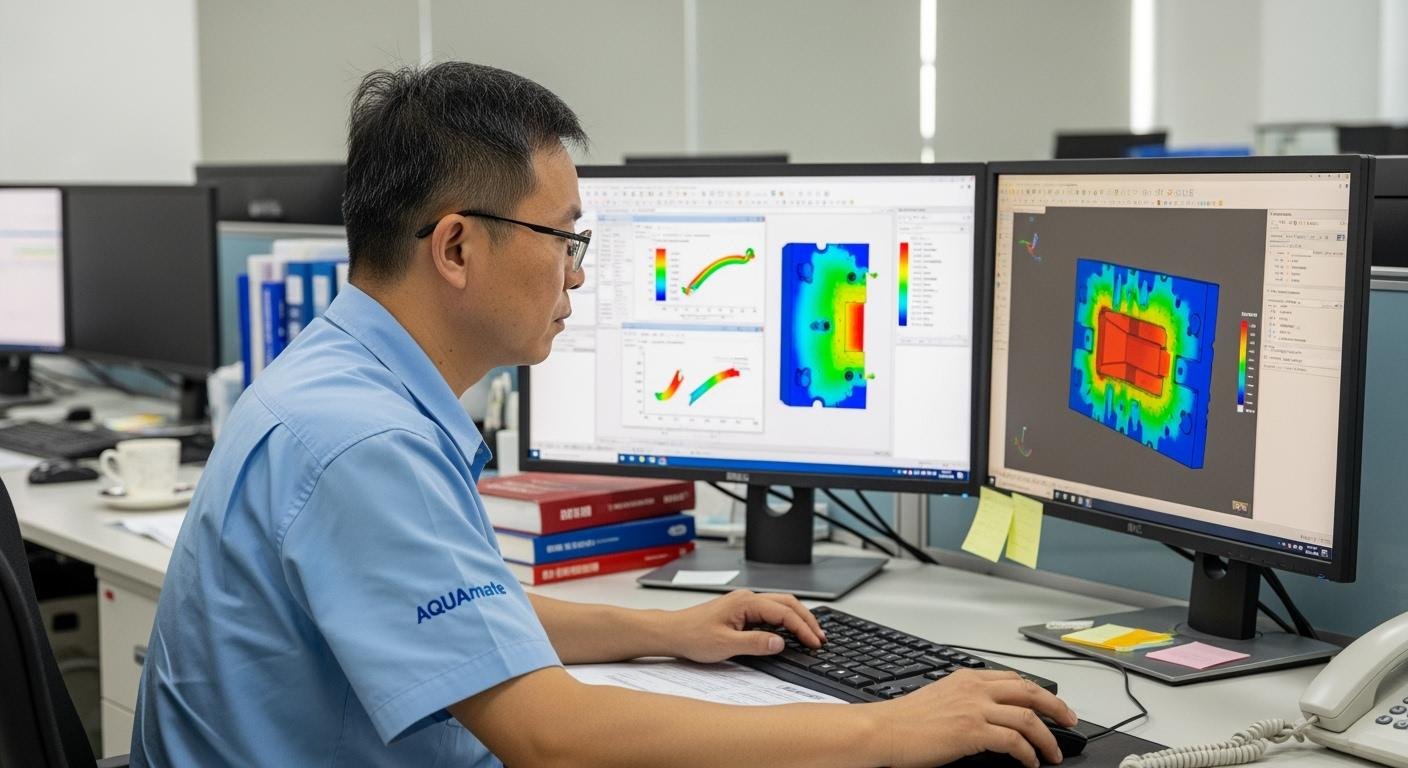

Step 2. Free DFM & Feasibility Review

Our engineering team performs a detailed DFM analysis and evaluates manufacturability at no cost.

Step 3. Feedback & Recommendations

We provide annotated drawings, design suggestions, and risk assessments related to molding, assembly, or materials.

Step 4. Prototype Sampling (Optional)

If needed, we produce samples to validate critical dimensions, fit, or performance before tooling.

A Value-Added Service, Always Free

ENGINEERING SUPPORT

Unlike some manufacturers who charge for engineering support, we view DFM analysis as a vital part of our partnership. It helps us build better tools, reduce trial-and-error cycles, and deliver consistent quality from the first run.

Whether you’re launching a new product or improving an existing one, our DFM expertise supports faster approvals, smoother production, and better long-term results.