Quality Management

From incoming materials to final product inspection, we ensure your products meet the highest standards every time.

QUALITY MANAGEMENT

Protecting Your Brand Through Quality

At AQUAmate Group, quality isn’t just a checkpoint, it’s built into every step of our process. With over 30 years of manufacturing experience, we’ve developed a robust quality management system that ensures reliability, consistency, and compliance across all projects. From raw material inspection to final product testing, our team is committed to delivering results that meet your exact specifications and protect your brand reputation.

How We Ensure Product Standards

Transparency at Every Stage

We provide clear communication, detailed inspection reports, and traceable documentation throughout the production cycle. Clients can access testing data, photos, and quality logs tied to specific batches or SKUs. This level of transparency allows for confident decision-making and faster approvals.

Real-Time Monitoring

We align technical development with production readiness, ensuring all components from materials to manufacturing processes are fully validated and synchronized before launch. This helps avoid last-minute surprises and ensures your product is launching on schedule.

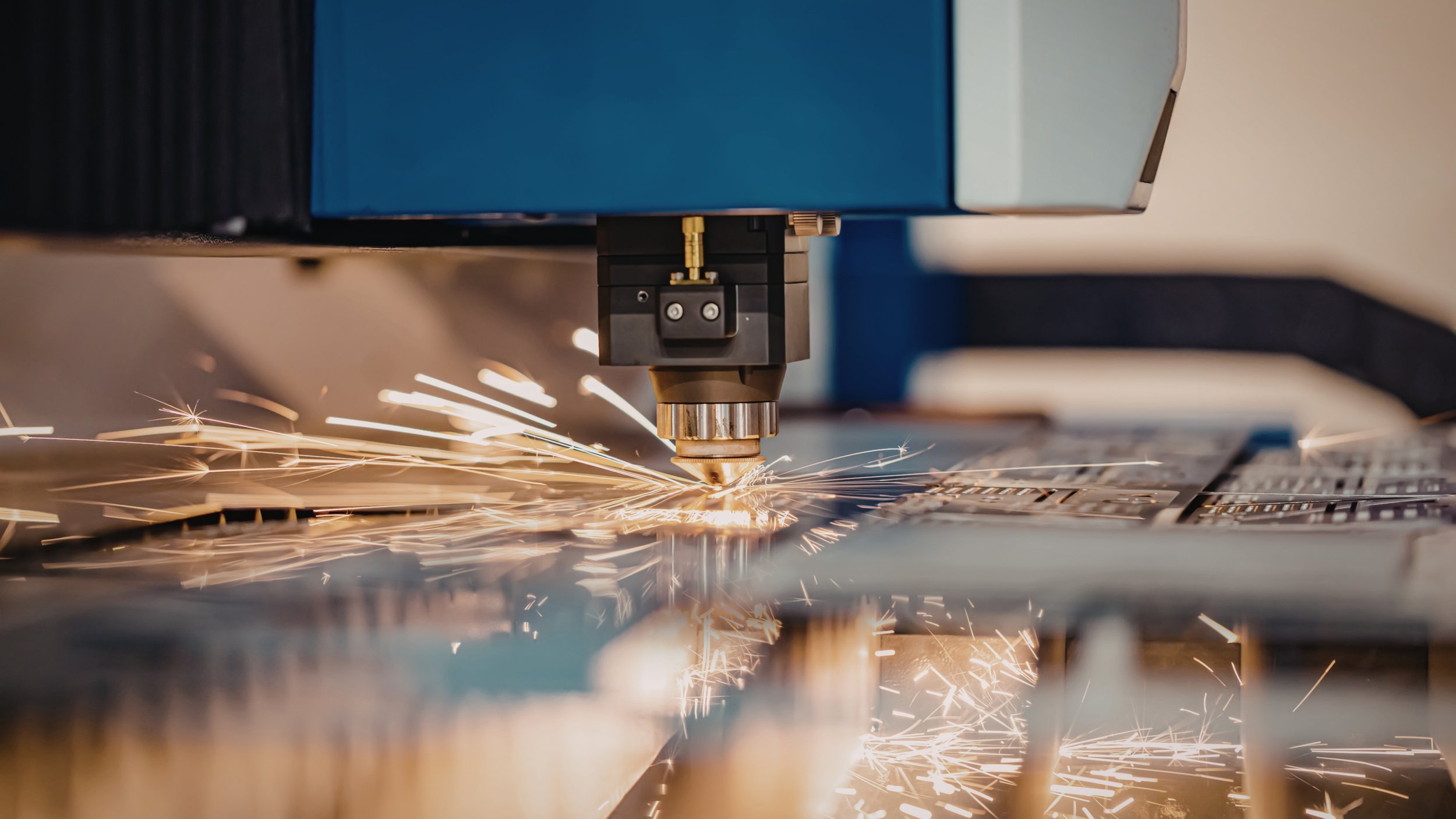

Automated Quality Processes

In areas where precision is critical, we integrate automated inspection tools, such as laser measurement, pressure test rigs, and torque sensors. These systems reduce human error and deliver consistent results. Automated alerts notify supervisors when a value is out of tolerance, ensuring fast response times.

Incoming and In-Line Checks

We inspect materials and components as they arrive to avoid defects entering the production line. During manufacturing, trained inspectors perform in-line quality checks at key stages. This includes surface inspections, fit-and-function tests, and sub-assembly verifications.

Final Inspection and Batch Release

Before shipment, we conduct batch-level inspections based on AQL sampling methods. Each lot is reviewed for visual quality, functionality, packaging, and labeling. Only approved batches are cleared for shipping. Inspection photos and reports are shared with clients for reference and documentation.

Feedback and Continuous Improvement

Every quality issue, no matter how minor, is logged and reviewed. We use this data to improve processes, update training, refine tools, and reduce error rates. Your feedback is incorporated into our internal systems to help us improve future production runs.

In-House Laboratory Testing

Unlike many manufacturers, we operate a fully equipped lab in our factory to test water pressure, flow rate, material durability, surface finish, and overall performance. All tests follow international standards, with results recorded for full traceability.

Learn More About Our Quality Management

For further information on quality management, please feel free to contact us.

Our Quality Management Process

We follow a streamlined, 5-step quality process to ensure every product meets high standards of performance, consistency, and compliance.

Step 1. Material Inspection

All incoming materials and components are checked for quality, consistency, and compliance before production begins.

Step 2. First Article & Setup Approval

We inspect initial samples from each production run to confirm dimensions, fit, and function before moving to mass production.

Step 3. In-Process Monitoring

Our QC team performs regular checks during production to ensure process stability.

Step 4. Functional & Final Inspection

Each batch undergoes performance testing (e.g. leak, flow, pressure) and final visual and dimensional inspection before approval.

Step 5. Packaging Verification & Traceability

We confirm packaging, labeling, and barcoding meet requirements. All results are documented for full traceability.

Lastest Articles

Stay up to date with our latest insights, tips, and industry news. From product trends to behind-the-scenes stories, our articles are here to inspire and inform.

FAQs

We know you might have a few questions, so we’ve put together some helpful answers to get you started. If you don’t find what you’re looking for, we’re always here to help!

-

We perform in-process and final inspections using quality checklists and tolerance guidelines.

-

Yes. Our in-house team oversees quality at every step, from incoming materials to packing.

-

Yes. We can coordinate with any inspection agency of your choice or recommend one locally.

-

We investigate the root cause, take corrective action, and replace or rework affected units as needed.

-

Yes. We offer inspection reports, test data, and compliance records based on your requirements.

-

Our procedures are aligned with ISO 9001 principles, and we can adapt to specific customer standards if required.

Sanitaryware is no longer just about functionality, it's about innovation, sustainability, and experience. As we look ahead to 2025 and beyond…