Surface Finishing Services Tailored to Your Product

In-house surface finishing for enhanced look and performance, fast, consistent, and quality-controlled.

Our Surface Finishing Capabilities

We offer a complete range of in-house surface finishing services designed to enhance both the appearance and performance of your products. With a dedicated plating plant and fully automated electroplating and spray coating lines, we ensure consistent quality, reduced cycle time, and precise control across every production batch.

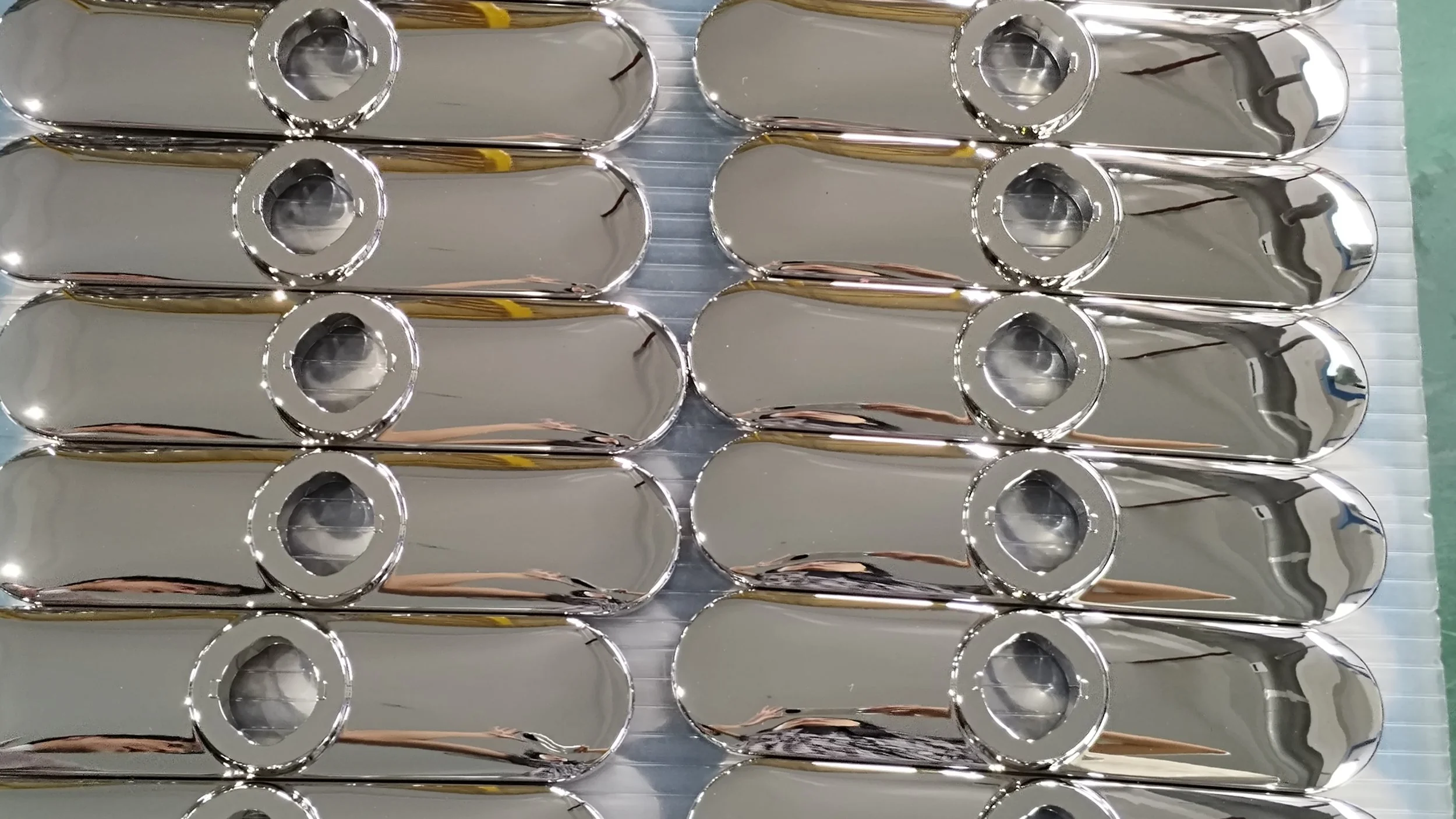

Electroplating

Our automated electroplating line produces high-quality chrome, nickel, and satin finishes on both metal and plastic substrates. Electroplating enhances corrosion resistance, surface hardness, and visual appeal. Each finish is tested for thickness, adhesion, and salt spray resistance.

Spray Painting

Applied via a fully automated line, spray coatings provide a uniform decorative or protective layer across plastic and metal parts. We support a variety of paint systems including matte, gloss, metallic, and soft-touch coatings. Color matching is available per Pantone or sample reference.

PVD Coating

PVD coating delivers ultra-thin, high-performance metal finishes with exceptional hardness, wear resistance, and aesthetic appeal. Using a vacuum deposition process, we apply durable decorative layers in a range of colors from classic gold and chrome to modern black and rose tones. Ideal for parts requiring both visual impact and long-lasting surface protection, PVD is perfect for electronics, hardware, and lifestyle products.

Brushed Nickel

Our brushed nickel finish delivers a sleek, contemporary appearance with fine, uniform brush lines that enhance both the visual appeal and corrosion resistance of your products—perfect for applications requiring both style and durability.

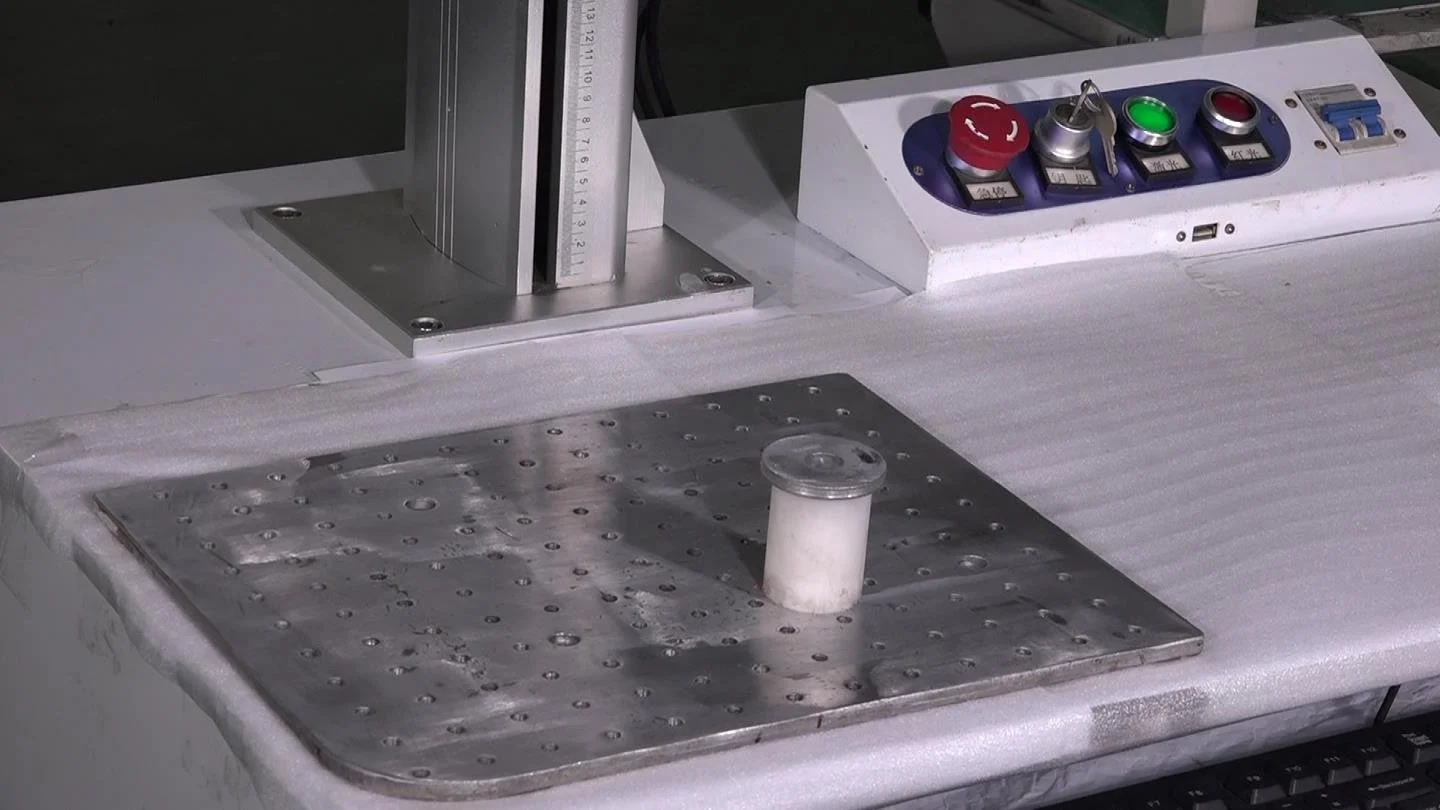

Laser Printing

Laser marking offers a permanent, high-resolution method for applying logos, serial numbers, or compliance information. It is suitable for both plastic and metal components, with excellent durability and precision.

Pad Printing

Ideal for branding, symbols, or multicolor graphics on curved or irregular surfaces. Our pad printing process supports fine-detail reproduction and strong ink adhesion across a range of substrates.

Blasting

Sand or glass bead blasting is used to create matte textures, remove surface defects, or prepare parts for subsequent treatments. This process ensures a clean, uniform surface ideal for anodizing or painting.

Anodizing

Anodizing strengthens aluminum surfaces through an electrochemical process that adds corrosion resistance and color options. Available in clear, black, and custom tones, this finish also improves wear resistance and product longevity.

Why Choose Our Finishing Services

Fully In-House Operation

All finishing processes are performed within our facility, allowing better lead time control, reduced transport handling, and tighter quality oversight.

Customizable Finishes

We work closely with clients to match colors, textures, or finishes to exact brand specifications or existing product lines.

Automated Precision

Our electroplating and spray coating lines are fully automated, ensuring high consistency and throughput for large-scale production.

Compliance Ready

Finishes are regularly tested and validated to meet CE, REACH, and other market-specific standards.

In-House Surface Finishing Facility

VERTICAL INTEGRATION

Our in-house surface finishing factory gives your products the cosmetic excellence they need to stand out in the market without relying on external suppliers. By keeping finishing processes under our own roof, we ensure better quality control, faster lead times, and greater flexibility throughout your project.

Lastest Articles

Stay up to date with our latest insights, tips, and industry news. From product trends to behind-the-scenes stories, our articles are here to inspire and inform.

Let’s Build Your Next Product Together

Looking to enhance the appearance, durability, or branding of your product?

Contact us to request finish samples or discuss a custom surface treatment plan.

Sanitaryware is no longer just about functionality, it's about innovation, sustainability, and experience. As we look ahead to 2025 and beyond…