Lead Time & Capacity

We are equipped to scale production quickly, supporting projects from concept development to mass manufacturing.

Scalable Production Capacity

VERTICAL INTEGRATION

At full operating capacity, our manufacturing facilities can produce between 2 million to 3 million pieces per month across plastic and metal categories. This high-volume capacity allows us to fulfill bulk orders, staggered shipments, and phased product rollouts, all while maintaining quality and consistency.

180-Day OEM Project Timeline

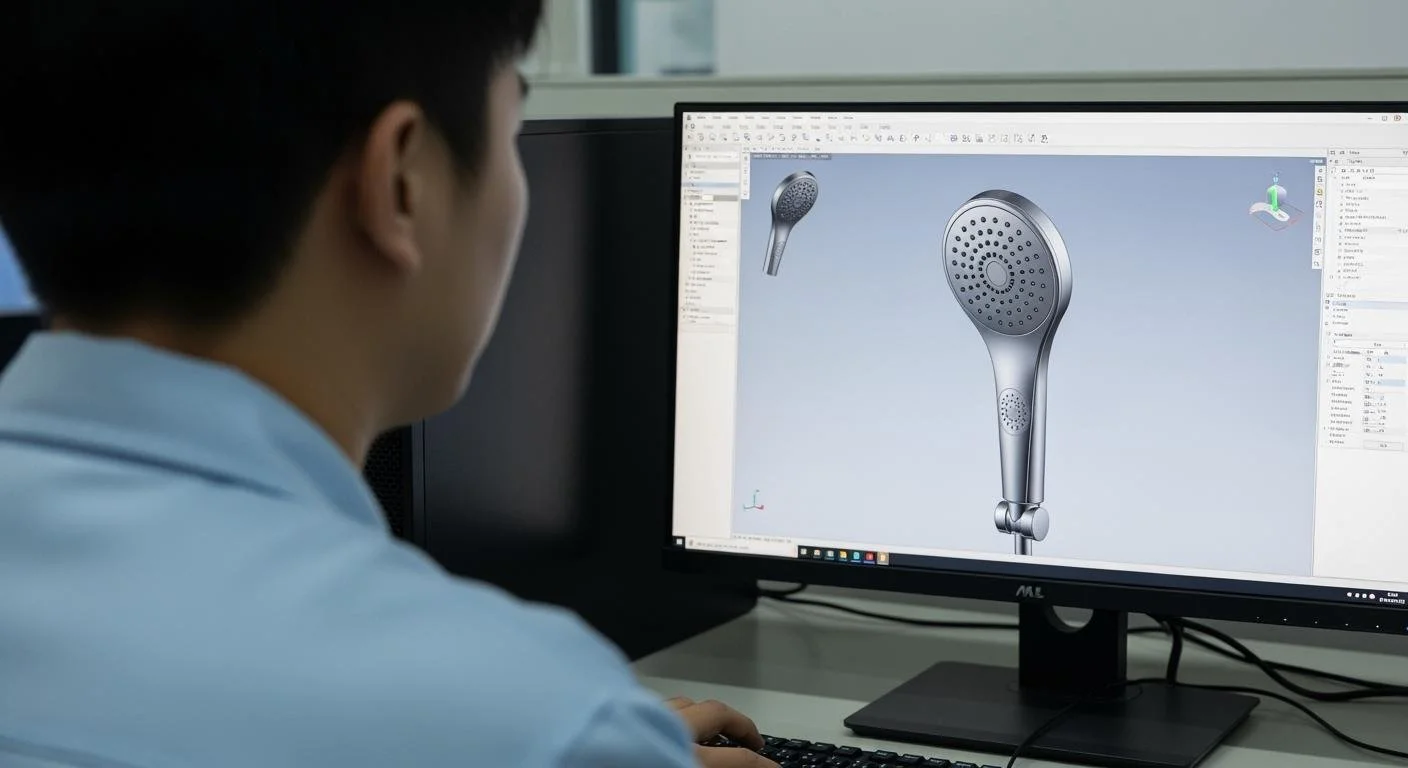

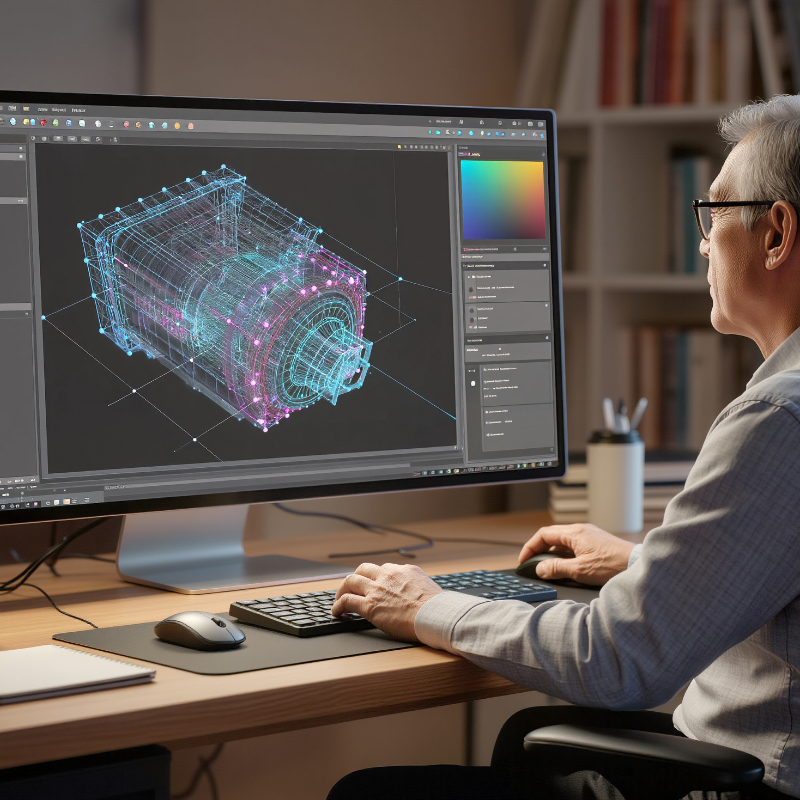

3D Modeling & Engineering Design

3D Modeling & Engineering Design

Duration: 2 weeks

Our team creates detailed 3D models and mechanical drawings to validate structure, function, and feasibility before prototyping. Includes DFM (Design for Manufacturing) input.

Duration: 2 weeks

Our team creates detailed 3D models and mechanical drawings to validate structure, function, and feasibility before prototyping. Includes DFM (Design for Manufacturing) input.

Functional Prototype

Functional Prototype

Duration: 7–10 working days (after final design)

We create a working prototype to test function, appearance, and assembly fit. This step helps reduce revisions during mold development.

Duration: 7–10 working days (after final design)

We create a working prototype to test function, appearance, and assembly fit. This step helps reduce revisions during mold development.

Mold Fabrication

Mold Fabrication

Duration: 45–60 days

Production tooling is built once the prototype is approved. Each mold is engineered for long-term use and can produce up to 500,000 pieces. Tooling is optimized for durability and part accuracy.

Duration: 45–60 days

Production tooling is built once the prototype is approved. Each mold is engineered for long-term use and can produce up to 500,000 pieces. Tooling is optimized for durability and part accuracy.

Injection Molding

Injection Molding

Duration: Varies by complexity and quantity

Once the mold is complete, we move into injection molding. We adjust machine scheduling and cycle times based on material, part size, and finish requirements.

Duration: Varies by complexity and quantity

Once the mold is complete, we move into injection molding. We adjust machine scheduling and cycle times based on material, part size, and finish requirements.

Trial 1 (T1) – Sample Run

Duration: 7–10 days

We conduct a small production run of approximately 100 pcs to test mold performance and part consistency. Once T1 is approved, packaging specifications are confirmed and locked in.

Trial 1 (T1) – Sample Run

Duration: 7–10 days

We conduct a small production run of approximately 100 pcs to test mold performance and part consistency. Once T1 is approved, packaging specifications are confirmed and locked in.

Mass Production

Mass Production

Plastic Parts Duration: 40-45 days

Metal Parts Duration: 60-65 days

Final production lead times begin after T1 approval and packaging confirmation. These timeframes include material procurement, molding, surface finishes, assembly (if applicable), and final packaging.

Plastic Parts Duration: 40-45 days

Metal Parts Duration: 60-65 days

Final production lead times begin after T1 approval and packaging confirmation. These timeframes include material procurement, molding, surface finishes, assembly (if applicable), and final packaging.

Need a lead time estimate for your project?

Contact us and we’ll prepare a detailed timeline based on your product specs and volume.