We help you validate product designs before full-scale production through proof of concept, engineering reviews, prototyping, and functional testing.

Product Design Validation

What Is Product Design Validation?

INTRODUCTION

Product Design Validation is the process of reviewing a 3D model or technical drawing to confirm that it’s suitable for mass production. Our engineering team evaluates your design for structural feasibility, material compatibility, assembly tolerance, and functional performance before any mold is built.

What We Check During the Review

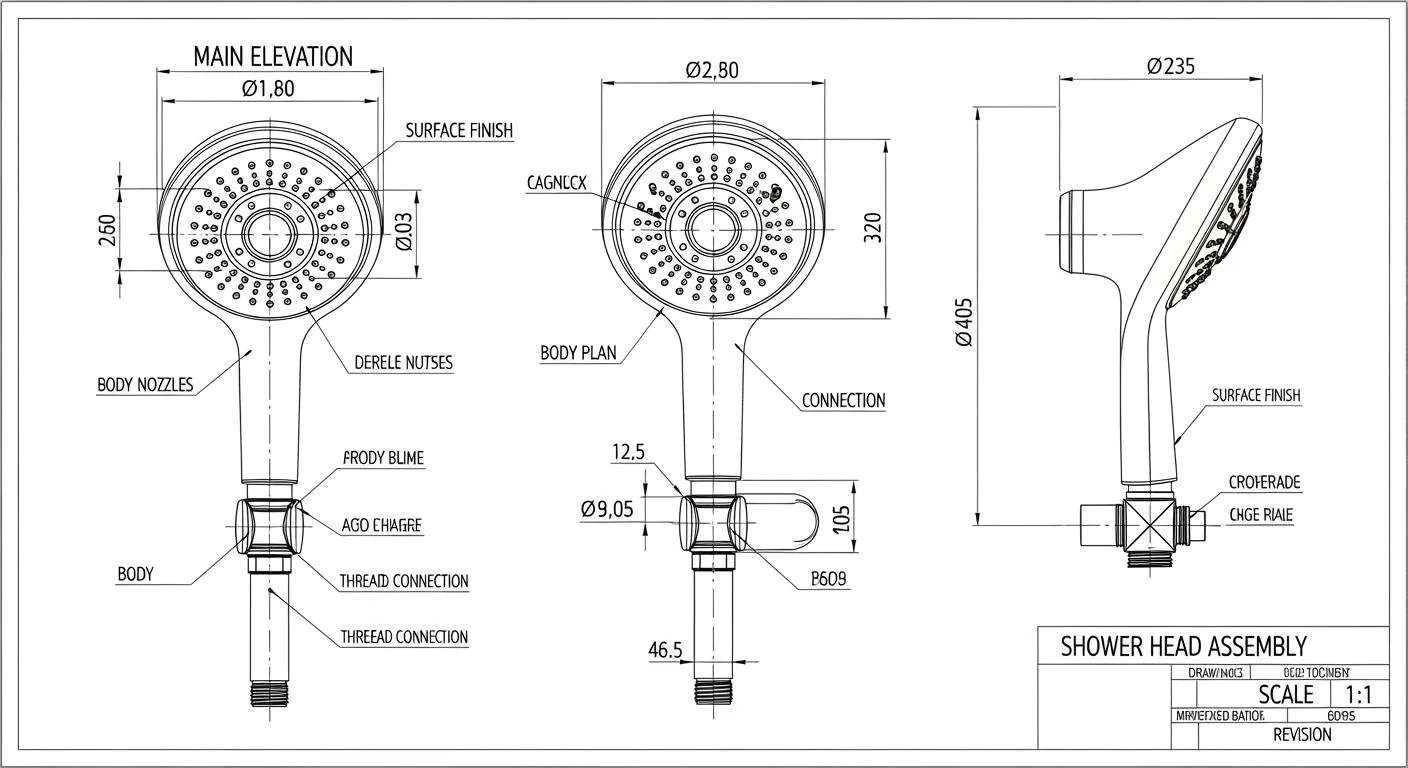

Our validation process includes a comprehensive technical audit of your design files (STEP, IGES, STL, or 2D drawings), covering:

Wall thickness consistency

Draft angles for mold release

Undercut detection

Rib and boss structures

Snap-fit and joint design

Material selection compatibility

Tolerance and fit between parts

Aesthetic surface requirements

Assembly considerations

Learn More About Design Validation

For further information on our design validation capability, please feel free to contact us.

WHY DESIGN VALIDATION MATTERS

Engineering Review for Manufacturability

Before moving into tooling or production, every design benefits from a second set of expert eyes. Our Product Design Validation capability provides an in-depth engineering review of your submitted design files, helping to identify potential issues, reduce costly revisions, and improve overall manufacturability.

Avoid unnecessary tooling revisions

Increase first-shot success rate in mold trials

Improve part performance and assembly fit

Protect your investment in tooling

Reduce lead time and rework

Launch with greater confidence and fewer risks

With over 30 years of engineering experience, we help teams and businesses at all stages of product development with our design validation capability. Whether you're launching your first plastic component or refining a complex mold for high-volume production, we help ensure your designs are manufacturable, efficient, and risk-free.

Who Benefits from This Service

Private label brands developing new products

Startups and small businesses entering plastic manufacturing for the first time

OEMs and design teams needing a second opinion before finalizing molds

Clients using export tools who want to avoid costly international revisions

How It Works

Here’s how our design validation step-by-step process works to support your path to production:

Submit Design Files

We accept STEP, IGES, STL, or 2D drawings

Initial Review

Our engineers assess manufacturability and performance

Feedback Report

Structured notes with annotations and suggestions

Design Adjustment (Optional)

We assist with rework if needed

Approval for Tooling

Once validated, your design moves confidently into mold fabrication

Ready to Validate Your Design?

Before you invest in tooling, let’s make sure your product is set up for success. We offer a free consultation, book a call with our engineering team today.