Image 1 of 1

Image 1 of 1

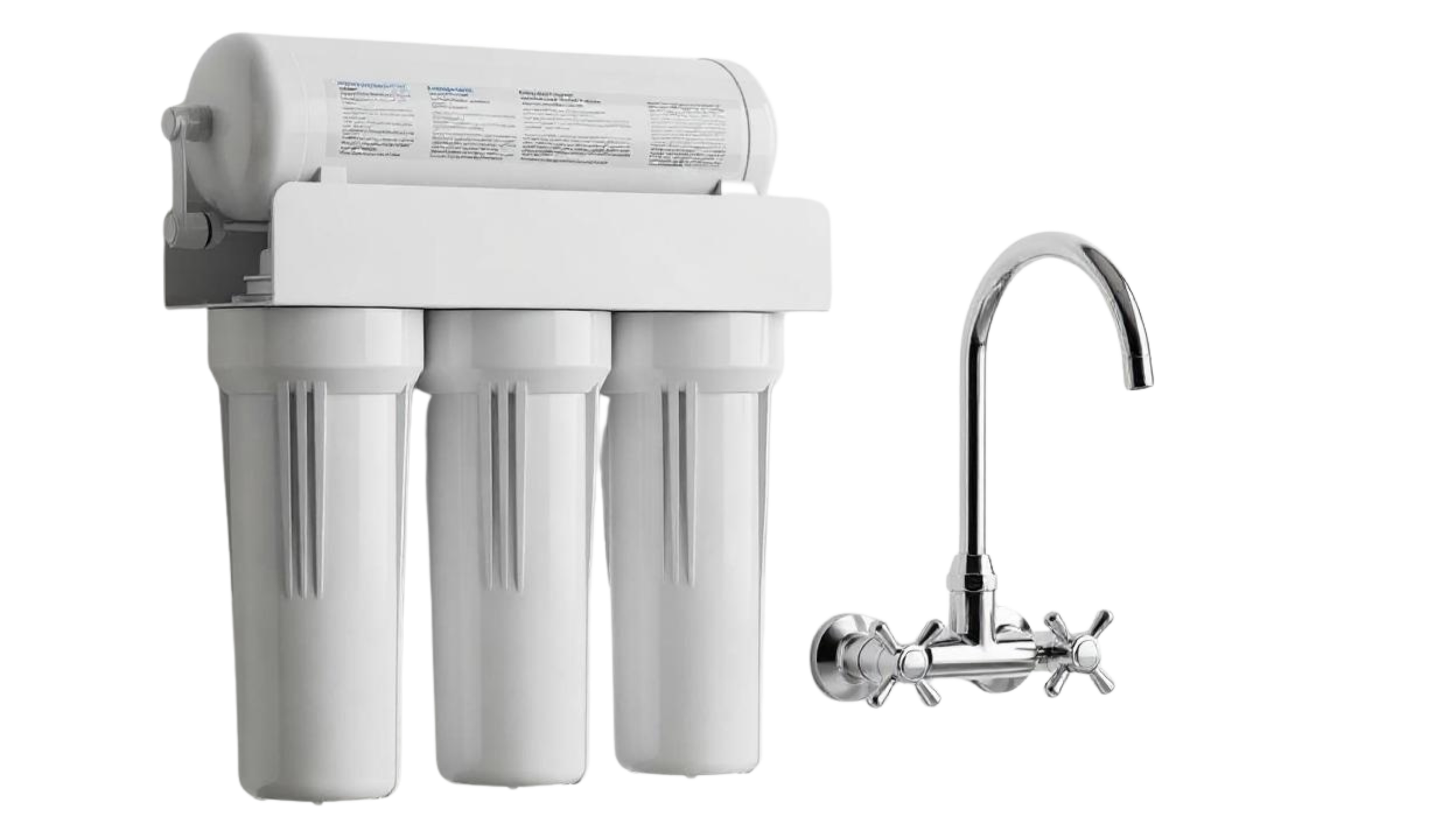

W-F303

Product Description

The W-F303 is a compact under-sink water filtration and storage system, ideal for household use where clean, great-tasting drinking water is essential. It combines a multi-stage filtration unit with a pressurized stainless steel storage tank and a dedicated faucet for direct dispensing. This system effectively removes:

Sand

Rust

Dirt

Chlorine

Organic contaminants

Heavy metals and bacteria (with RO membrane option)

It is suitable for kitchens, break rooms, or office pantries where space-saving and high-quality filtration are key.

Size

Dimensions (L × W × H): 20cm × 6 cm ×31 cm Stainless Steel and Plastic

Material

Housing material: Combination of stainless steel (for the storage tank) and durable food-grade plastic (for the filter housing), designed to resist corrosion and provide long-term performance.

Filter components:

Sediment filter (PP cotton): Removes large particles such as sand, rust, and dirt.

Activated carbon filter: Reduces chlorine, odors, and organic contaminants.

RO membrane (optional): Filters out heavy metals, bacteria, and dissolved solids (if configured as an RO system).

Post-carbon filter: Enhances taste and ensures clean, fresh water at the point of use.

Storage tank: Pressurized stainless steel tank for storing filtered water, ensuring a consistent supply and maintaining hygiene.

Faucet: Chrome-plated metal faucet for direct dispensing of purified water.

Tubing & connectors: BPA-free plastic tubing and quick-connect fittings for secure, leak-free installation.

Sealing components: Silicone or rubber O-rings to maintain pressure-tight seals throughout the system.

Production Steps

Material preparation: Source stainless steel tank, plastic filter housings, filtration media (PP, carbon), tubing, faucet, and connectors.

Molding and tank fabrication: Produce plastic parts via injection molding and stainless steel tank components through welding and polishing.

Filter cartridge assembly: Pack and seal sediment and carbon filters according to design specifications.

System assembly: Install filters into housings, attach tubing, connect the tank and faucet, and assemble the complete filtration unit.

Leak and pressure testing: Conduct rigorous tests to ensure all connections are sealed and the system operates under pressure without leaks.

Final inspection: Check visual quality, flow rate, and filtration performance.

Packaging: Carefully package the full unit with installation accessories and instructions, ready for distribution.

Product Description

The W-F303 is a compact under-sink water filtration and storage system, ideal for household use where clean, great-tasting drinking water is essential. It combines a multi-stage filtration unit with a pressurized stainless steel storage tank and a dedicated faucet for direct dispensing. This system effectively removes:

Sand

Rust

Dirt

Chlorine

Organic contaminants

Heavy metals and bacteria (with RO membrane option)

It is suitable for kitchens, break rooms, or office pantries where space-saving and high-quality filtration are key.

Size

Dimensions (L × W × H): 20cm × 6 cm ×31 cm Stainless Steel and Plastic

Material

Housing material: Combination of stainless steel (for the storage tank) and durable food-grade plastic (for the filter housing), designed to resist corrosion and provide long-term performance.

Filter components:

Sediment filter (PP cotton): Removes large particles such as sand, rust, and dirt.

Activated carbon filter: Reduces chlorine, odors, and organic contaminants.

RO membrane (optional): Filters out heavy metals, bacteria, and dissolved solids (if configured as an RO system).

Post-carbon filter: Enhances taste and ensures clean, fresh water at the point of use.

Storage tank: Pressurized stainless steel tank for storing filtered water, ensuring a consistent supply and maintaining hygiene.

Faucet: Chrome-plated metal faucet for direct dispensing of purified water.

Tubing & connectors: BPA-free plastic tubing and quick-connect fittings for secure, leak-free installation.

Sealing components: Silicone or rubber O-rings to maintain pressure-tight seals throughout the system.

Production Steps

Material preparation: Source stainless steel tank, plastic filter housings, filtration media (PP, carbon), tubing, faucet, and connectors.

Molding and tank fabrication: Produce plastic parts via injection molding and stainless steel tank components through welding and polishing.

Filter cartridge assembly: Pack and seal sediment and carbon filters according to design specifications.

System assembly: Install filters into housings, attach tubing, connect the tank and faucet, and assemble the complete filtration unit.

Leak and pressure testing: Conduct rigorous tests to ensure all connections are sealed and the system operates under pressure without leaks.

Final inspection: Check visual quality, flow rate, and filtration performance.

Packaging: Carefully package the full unit with installation accessories and instructions, ready for distribution.