Image 1 of 1

Image 1 of 1

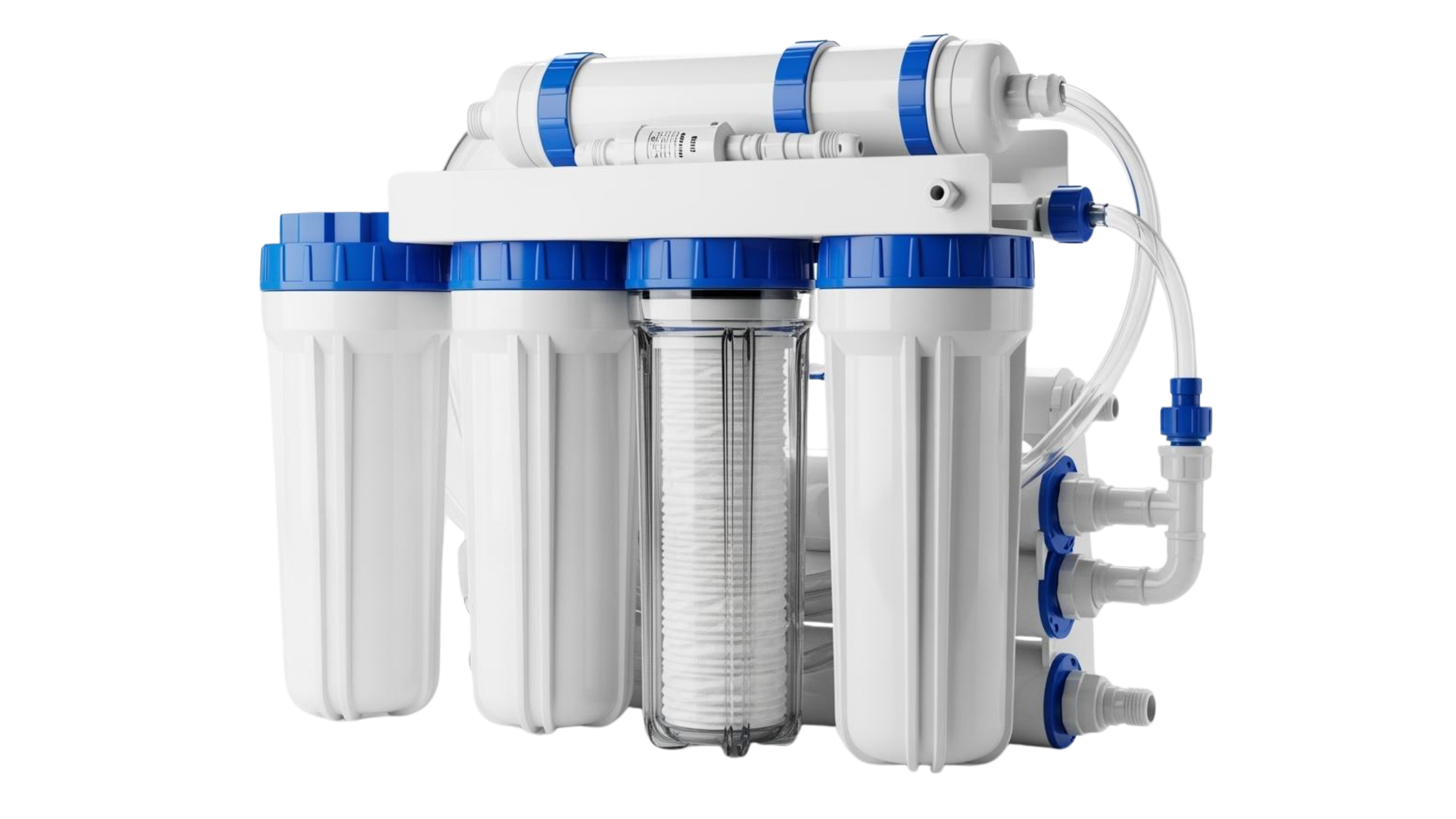

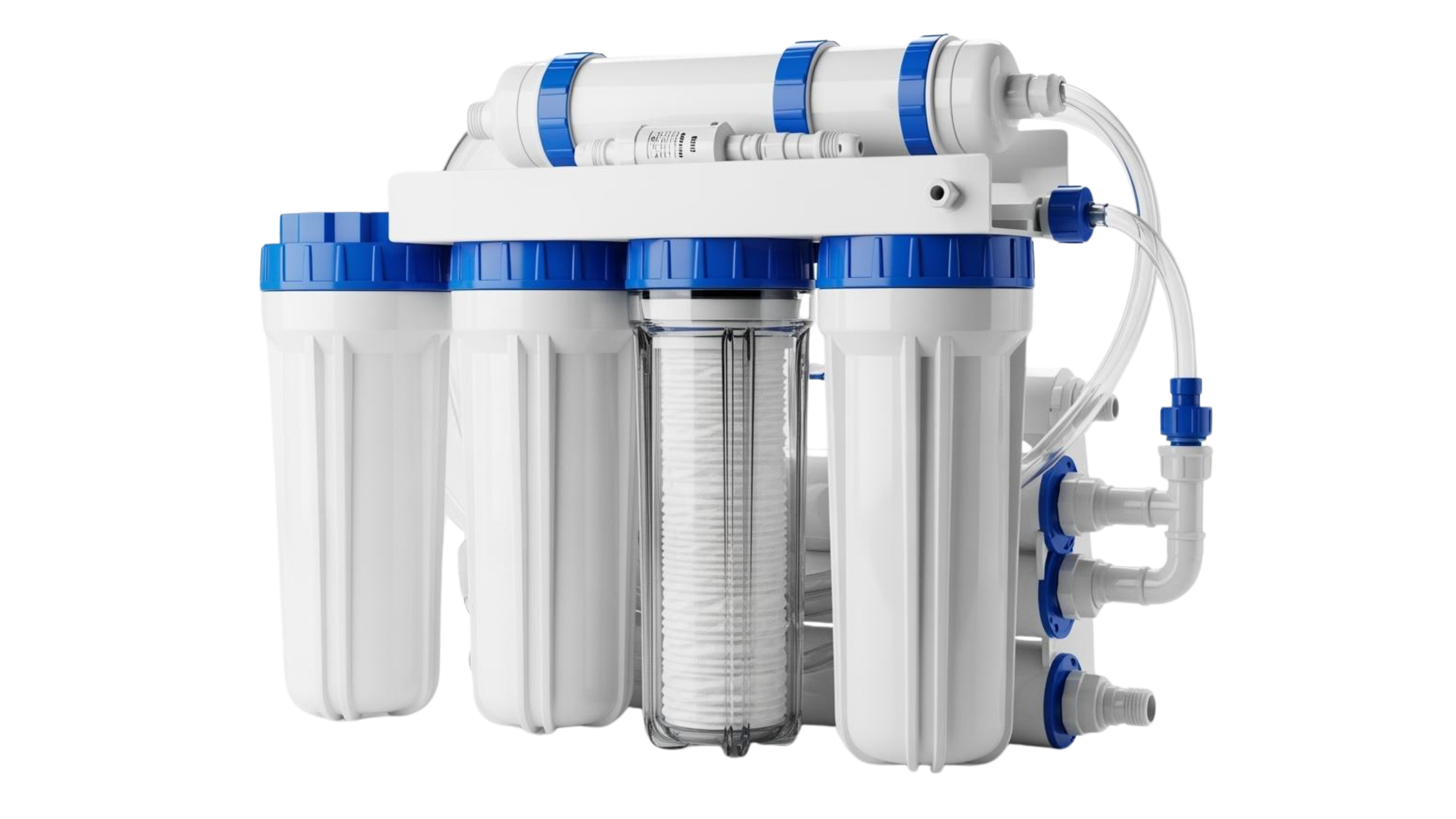

W-F302

Product Description

The W-F302 is a multi-stage reverse osmosis (RO) water filtration system, engineered for high-efficiency purification in residential or light commercial settings. With a comprehensive 5–6 stage filtration process, it delivers exceptionally pure water by removing a wide spectrum of contaminants including:

Sand and rust

Chlorine and odors

Heavy metals

Fluoride and nitrates

Organic compounds

Bacteria and dissolved solids

The W-F302 is ideal for households seeking ultra-clean, great-tasting water and features easy-to-install, food-grade components.

Size

Dimensions (L × W × H): 50cm × 6 cm ×30 cm

Material

Housing material: High-quality food-grade plastic, ensuring durability, chemical resistance, and long-term use in water filtration systems.

Filter system: Multi-stage reverse osmosis (RO) filtration unit, typically composed of:

Sediment filter (PP): Removes sand, rust, and large particles.

Granular activated carbon (GAC): Reduces chlorine, odors, and organic compounds.

Carbon block (CTO): Further purifies taste and removes residual chemicals.

Reverse osmosis membrane: Removes heavy metals, fluoride, nitrates, and other dissolved solids.

Post carbon filter: Polishes taste and ensures clean, fresh water output.

Optional mineral or alkaline filter: Adds beneficial minerals back into the purified water.

Connectors & tubing: BPA-free plastic tubing and quick-connect fittings for easy installation and secure water flow.

Sealing components: Silicone O-rings and gaskets to ensure leak-proof performance throughout the system.

Production Steps

Raw material sourcing: Gather food-grade plastic components, filter media (PP, activated carbon, RO membrane), tubing, valves, and fittings.

Molded housing manufacturing: Use injection molding to produce filter housings, caps, and brackets.

Filter cartridge production: Assemble each stage of the filtration system with appropriate media and quality control checks.

System assembly: Install the filters into the multi-stage housing unit, connect tubing, and secure all joints with sealing rings.

Leak and pressure testing: Test the full system under simulated operating pressure to verify sealing and flow performance.

Final inspection: Check assembly accuracy, appearance, and functionality.

Packaging: Carefully pack the complete RO unit with installation instructions and accessories, ready for shipment.

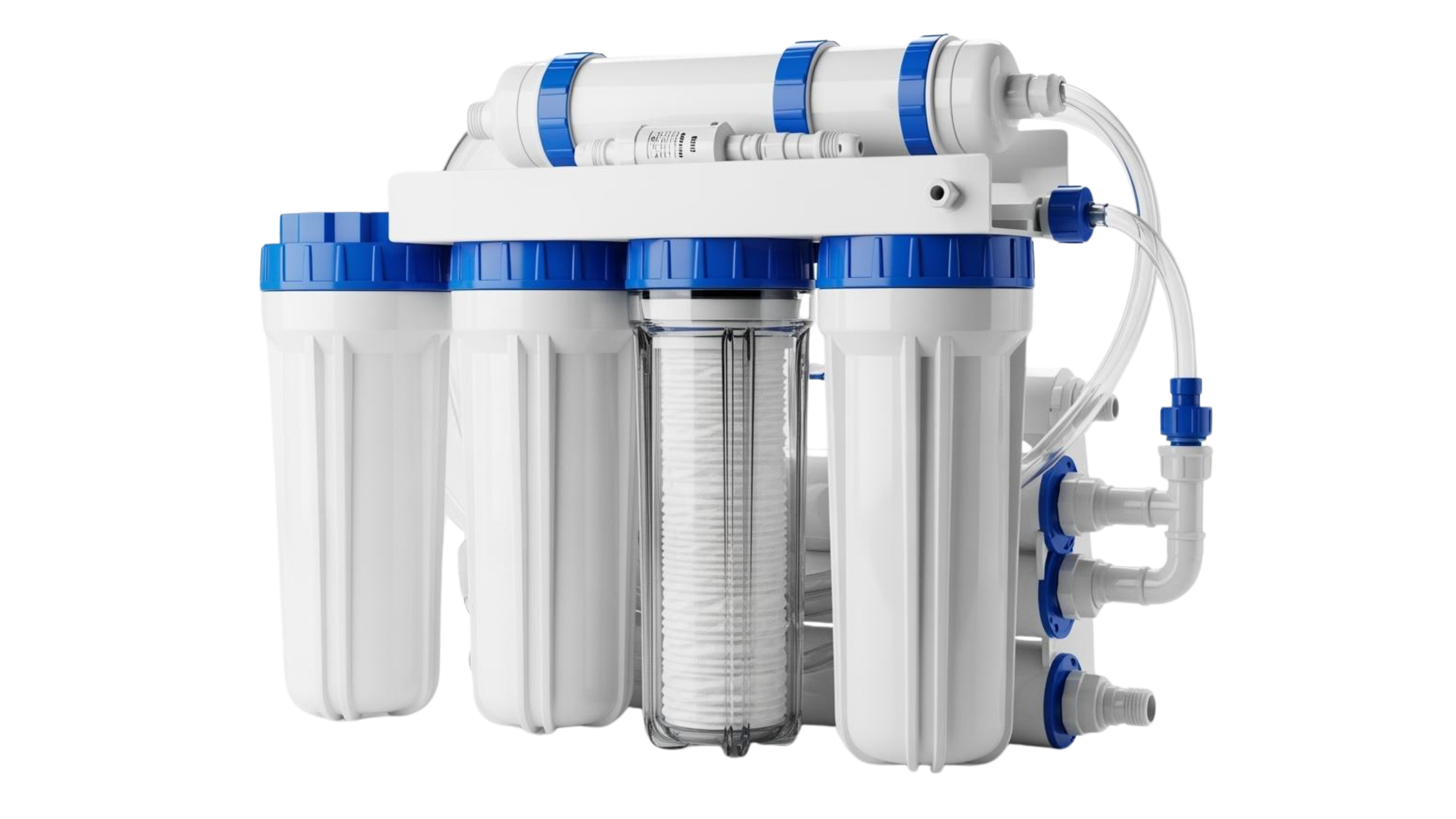

Product Description

The W-F302 is a multi-stage reverse osmosis (RO) water filtration system, engineered for high-efficiency purification in residential or light commercial settings. With a comprehensive 5–6 stage filtration process, it delivers exceptionally pure water by removing a wide spectrum of contaminants including:

Sand and rust

Chlorine and odors

Heavy metals

Fluoride and nitrates

Organic compounds

Bacteria and dissolved solids

The W-F302 is ideal for households seeking ultra-clean, great-tasting water and features easy-to-install, food-grade components.

Size

Dimensions (L × W × H): 50cm × 6 cm ×30 cm

Material

Housing material: High-quality food-grade plastic, ensuring durability, chemical resistance, and long-term use in water filtration systems.

Filter system: Multi-stage reverse osmosis (RO) filtration unit, typically composed of:

Sediment filter (PP): Removes sand, rust, and large particles.

Granular activated carbon (GAC): Reduces chlorine, odors, and organic compounds.

Carbon block (CTO): Further purifies taste and removes residual chemicals.

Reverse osmosis membrane: Removes heavy metals, fluoride, nitrates, and other dissolved solids.

Post carbon filter: Polishes taste and ensures clean, fresh water output.

Optional mineral or alkaline filter: Adds beneficial minerals back into the purified water.

Connectors & tubing: BPA-free plastic tubing and quick-connect fittings for easy installation and secure water flow.

Sealing components: Silicone O-rings and gaskets to ensure leak-proof performance throughout the system.

Production Steps

Raw material sourcing: Gather food-grade plastic components, filter media (PP, activated carbon, RO membrane), tubing, valves, and fittings.

Molded housing manufacturing: Use injection molding to produce filter housings, caps, and brackets.

Filter cartridge production: Assemble each stage of the filtration system with appropriate media and quality control checks.

System assembly: Install the filters into the multi-stage housing unit, connect tubing, and secure all joints with sealing rings.

Leak and pressure testing: Test the full system under simulated operating pressure to verify sealing and flow performance.

Final inspection: Check assembly accuracy, appearance, and functionality.

Packaging: Carefully pack the complete RO unit with installation instructions and accessories, ready for shipment.