Image 1 of 1

Image 1 of 1

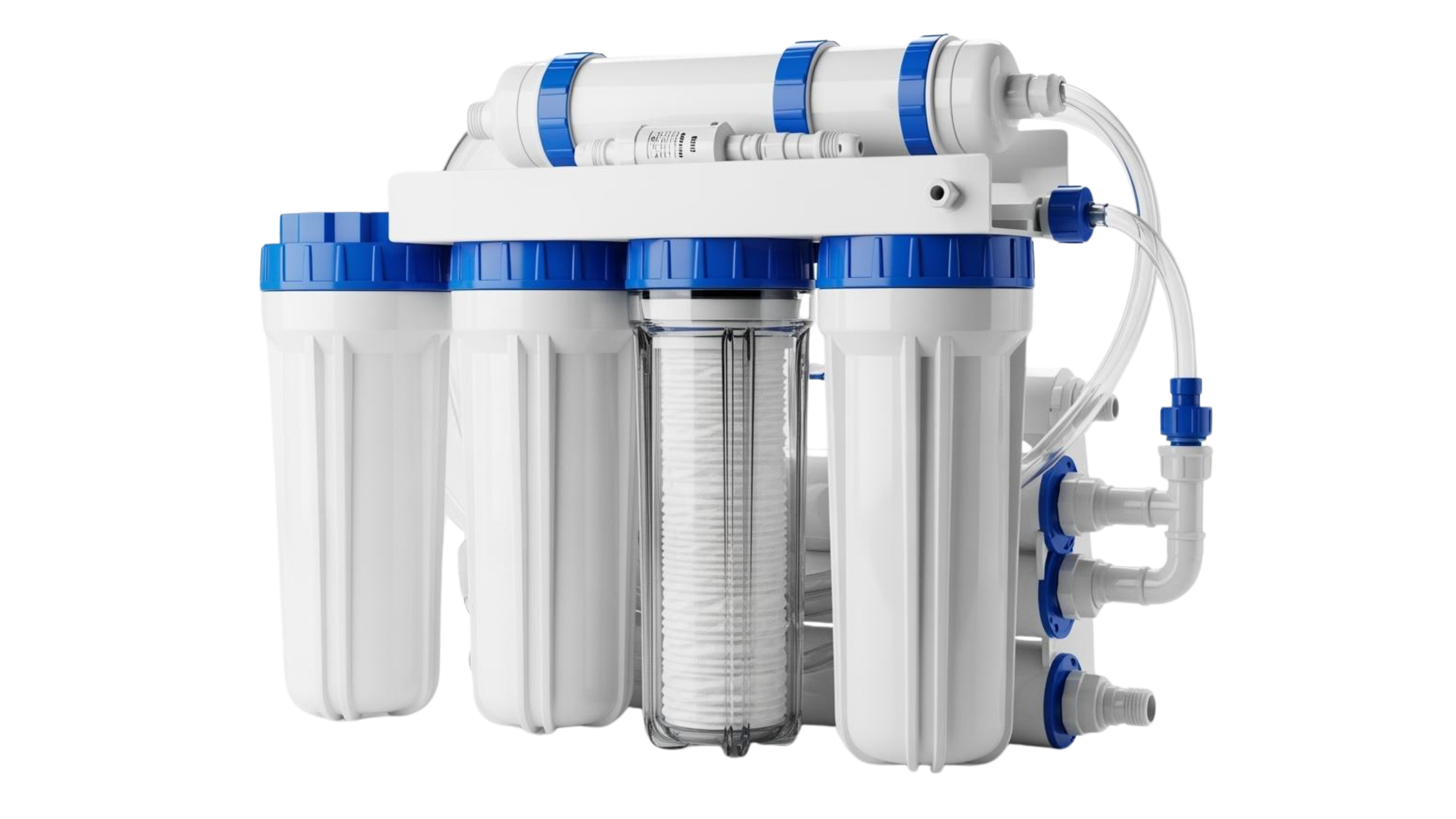

W-F301

Product Description

The W-F301 is a multi-stage water filtration system designed for high-performance residential or commercial use. With its robust stainless steel outer housing and high-pressure plastic filter housings, it delivers reliable filtration for kitchens, utility rooms, and under-sink installations. It effectively removes:

Sand

Dust

Rust

Chlorine

Chemical contaminants

Finer particles, bacteria, and dissolved solids (with optional ultrafiltration or RO membrane)

This system provides comprehensive water purification and improves both the safety and taste of drinking water.

Size

Dimensions (L × W × H): 20cm × 6 cm ×30 cm Stainless Steel and Plastic

Material

Outer housing: Constructed with stainless steel, providing a sleek and corrosion-resistant exterior ideal for long-term use in kitchen or utility spaces.

Filter housings: Made of durable, high-pressure-resistant plastic in blue and white, designed to protect and contain the internal filtration components.

Filtration system: Multi-stage design, typically including:

Stage 1 – Sediment filter (PP cotton): Removes visible particles like sand, dust, and rust.

Stage 2 – Carbon filter (CTO or GAC): Adsorbs chlorine, chemical contaminants, and improves taste and odor.

Stage 3 – Optional ultrafiltration or RO membrane (not visible but commonly included in systems of this type): Targets finer particles, bacteria, and dissolved solids.

Tubing and connectors: Food-grade plastic or polyethylene tubing with quick-connect fittings for safe and simple installation.

Seals and gaskets: Silicone or rubber O-rings used at all connection points to ensure leak-proof operation.

Production Steps

Material preparation: Stainless steel cylinders are cut, polished, and shaped for the main outer housing. Plastic parts are injection molded.

Filter cartridge manufacturing: Fabricate internal filters using PP cotton and activated carbon media. Assemble and seal into standard cartridges.

System assembly:

Mount filter housings to the main frame.

Install cartridges in correct flow sequence.

Connect stainless steel housing with inlet/outlet ports and tubing.

Electronic module (if applicable): Some models include a pump or control valve—these are integrated and sealed during this stage.

Leak and pressure testing: System is run under simulated water pressure to test for durability and seal integrity.

Final inspection: Check the complete unit for appearance, performance, and labeling accuracy.

Packaging: Securely pack with protective foam, tubing, installation accessories, and an instruction manual for end-user convenience.

Product Description

The W-F301 is a multi-stage water filtration system designed for high-performance residential or commercial use. With its robust stainless steel outer housing and high-pressure plastic filter housings, it delivers reliable filtration for kitchens, utility rooms, and under-sink installations. It effectively removes:

Sand

Dust

Rust

Chlorine

Chemical contaminants

Finer particles, bacteria, and dissolved solids (with optional ultrafiltration or RO membrane)

This system provides comprehensive water purification and improves both the safety and taste of drinking water.

Size

Dimensions (L × W × H): 20cm × 6 cm ×30 cm Stainless Steel and Plastic

Material

Outer housing: Constructed with stainless steel, providing a sleek and corrosion-resistant exterior ideal for long-term use in kitchen or utility spaces.

Filter housings: Made of durable, high-pressure-resistant plastic in blue and white, designed to protect and contain the internal filtration components.

Filtration system: Multi-stage design, typically including:

Stage 1 – Sediment filter (PP cotton): Removes visible particles like sand, dust, and rust.

Stage 2 – Carbon filter (CTO or GAC): Adsorbs chlorine, chemical contaminants, and improves taste and odor.

Stage 3 – Optional ultrafiltration or RO membrane (not visible but commonly included in systems of this type): Targets finer particles, bacteria, and dissolved solids.

Tubing and connectors: Food-grade plastic or polyethylene tubing with quick-connect fittings for safe and simple installation.

Seals and gaskets: Silicone or rubber O-rings used at all connection points to ensure leak-proof operation.

Production Steps

Material preparation: Stainless steel cylinders are cut, polished, and shaped for the main outer housing. Plastic parts are injection molded.

Filter cartridge manufacturing: Fabricate internal filters using PP cotton and activated carbon media. Assemble and seal into standard cartridges.

System assembly:

Mount filter housings to the main frame.

Install cartridges in correct flow sequence.

Connect stainless steel housing with inlet/outlet ports and tubing.

Electronic module (if applicable): Some models include a pump or control valve—these are integrated and sealed during this stage.

Leak and pressure testing: System is run under simulated water pressure to test for durability and seal integrity.

Final inspection: Check the complete unit for appearance, performance, and labeling accuracy.

Packaging: Securely pack with protective foam, tubing, installation accessories, and an instruction manual for end-user convenience.