Beyond Surface: How AQUAmate Ensured Exact PVD Finishing for a U.S. Sanitary Brand

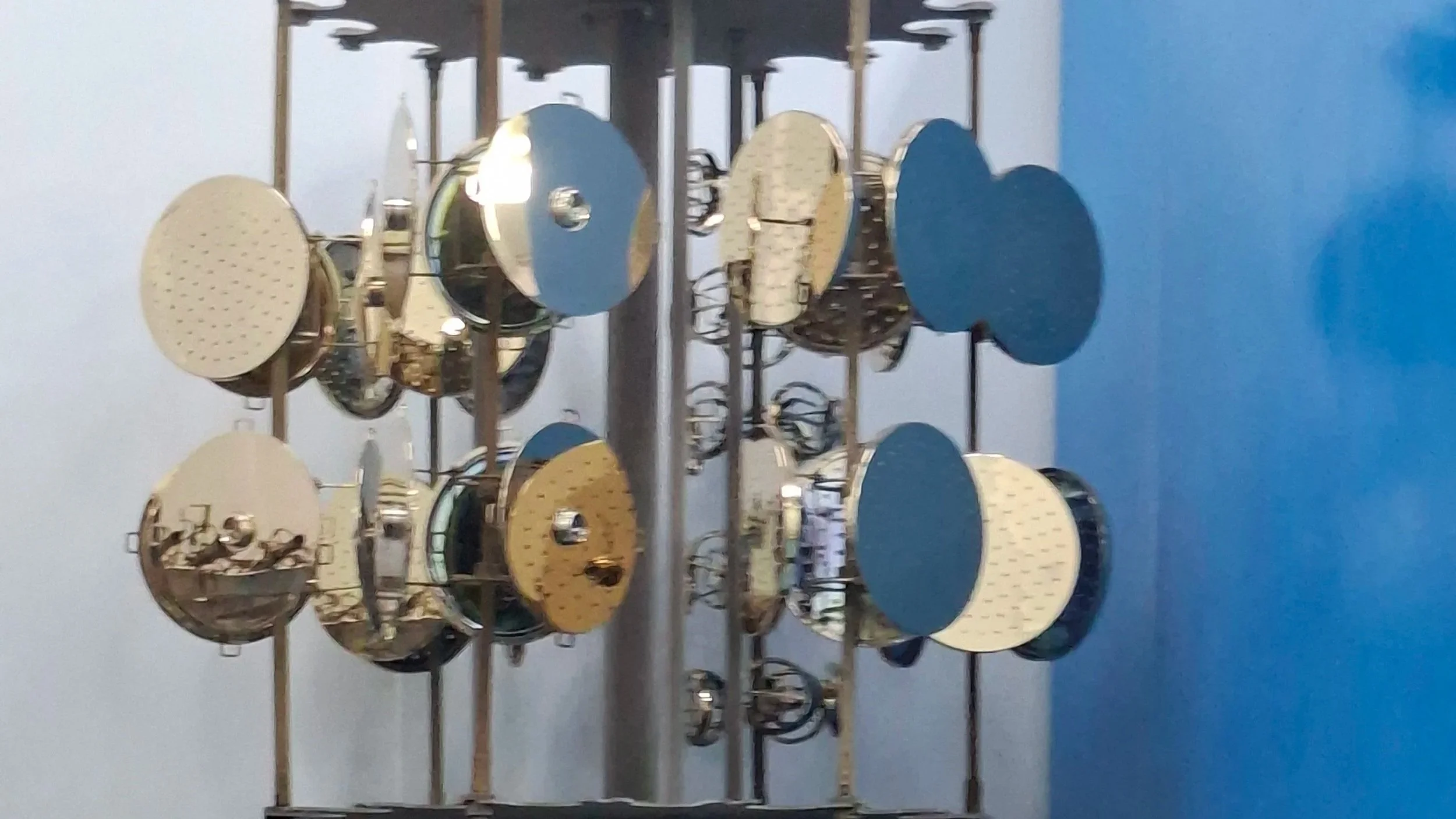

Our In-house PVD Coating Machine In Action

Meeting Expectations Down to the Last Detail

At AQUAmate, we believe that true manufacturing excellence means more than just producing at scale, it means matching the expectations, quality, and brand vision of our clients down to the finest detail.

One of our long-standing customers from the United States, a premium sanitary brand, had a very specific requirement: the exact PVD (Physical Vapor Deposition) surface finish used in their own production facilities. From the showerhead body to the smallest accessory component, the color tone, texture, and durability of the finish were critical to their brand identity.

They didn’t want something “close enough.” They needed absolute consistency across regions, across facilities, and across production batches.

Taking Action: Investing in the Same PVD Machine Model

To meet this unique requirement, we made a strategic and customer-focused decision:

We invested in the exact same model of PVD machine used by our customer in the U.S.

This was not a small decision. PVD coating systems are highly specialized and significant capital investments. But we understood that to truly align with our customer’s quality and aesthetic standards, we needed to match their capabilities, not approximate them.

By replicating their equipment, we ensured that the color tone, layer thickness, adhesion, and surface uniformity of the PVD finish would be virtually identical to what they produce in their own facility.

How This Benefits Our Customer

This action had a direct and meaningful impact on our customer’s business:

✅ Color Consistency Across Global Production

With identical PVD equipment, the product finish from our factories now matches seamlessly with their U.S.-made components. This consistency is critical for brand integrity and consumer satisfaction.✅ Reduced Quality Discrepancies

By eliminating the variation that often comes from using different machines or coating processes, we significantly lowered the risk of rework, returns, or mismatched batches.✅ Faster Approval Time

Product samples and new developments can now be approved faster because the finish quality is immediately familiar and acceptable to our client’s engineers and quality control team.✅ Stronger Supply Chain Integration

Our customer can now treat our production facility as an extension of their own with shared standards, equipment, and expectations.✅ Peace of Mind

Our investment gives the customer confidence that we are committed not just to making products but to making their products the way they envision them.

Growing Together, Aligned in Vision

At AQUAmate, we don’t just deliver what’s asked, we anticipate what’s needed to ensure long-term success. By aligning with our client’s equipment and processes, we prove our readiness to grow with them, not just for them.

This is how we define partnership:

We listen to our clients’ needs

We invest in the right capabilities

We deliver products that match their vision in quality, design, and performance

We see every project not just as a transaction, but as a collaborative journey. When our customers elevate their standards, we rise with them.

Our Promise: Beyond Manufacturing

This case reflects a broader philosophy that defines AQUAmate:

We invest in what matters because we invest in our customers.

Whether it’s building new filter production lines, designing custom tooling, or acquiring the exact PVD machine a client uses, we go the extra mile because we are not just a supplier, we are a strategic partner.

Bring Your Vision to Life with AQUAmate

If you’re looking for a manufacturer who will match your standards, invest in your success, and grow alongside your brand, we are ready.

Let’s build something exceptional, together.